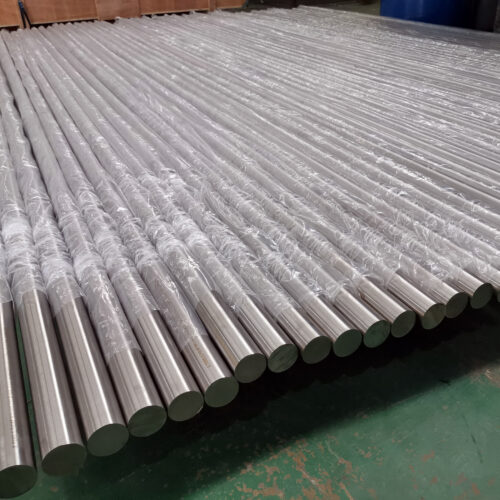

Production, Grades, and Customization Services

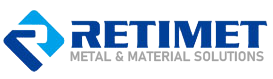

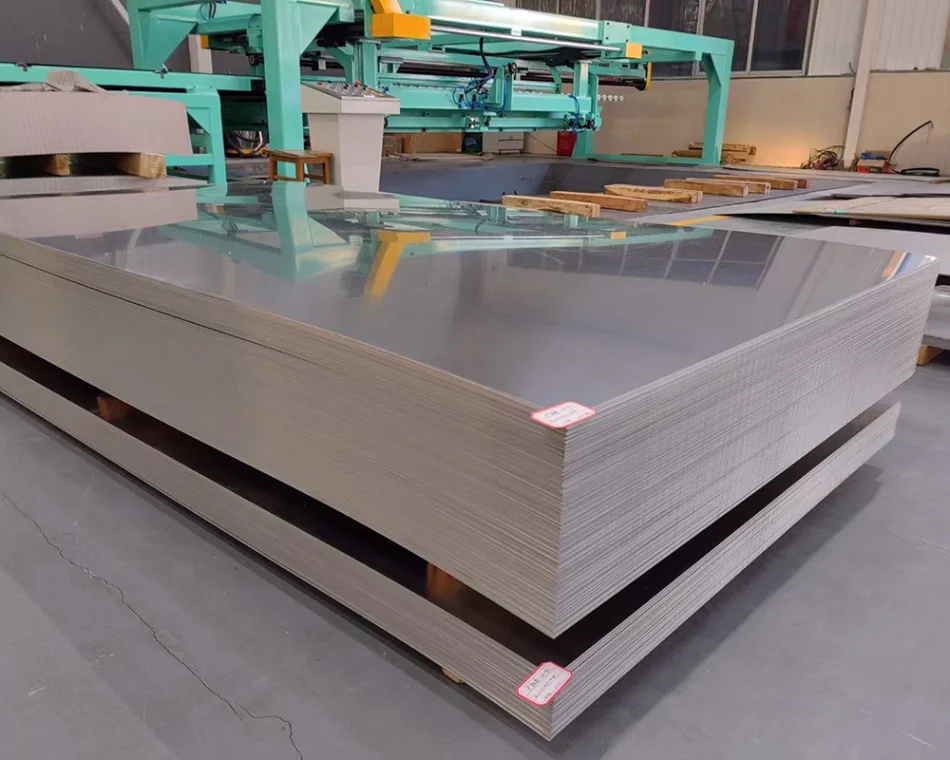

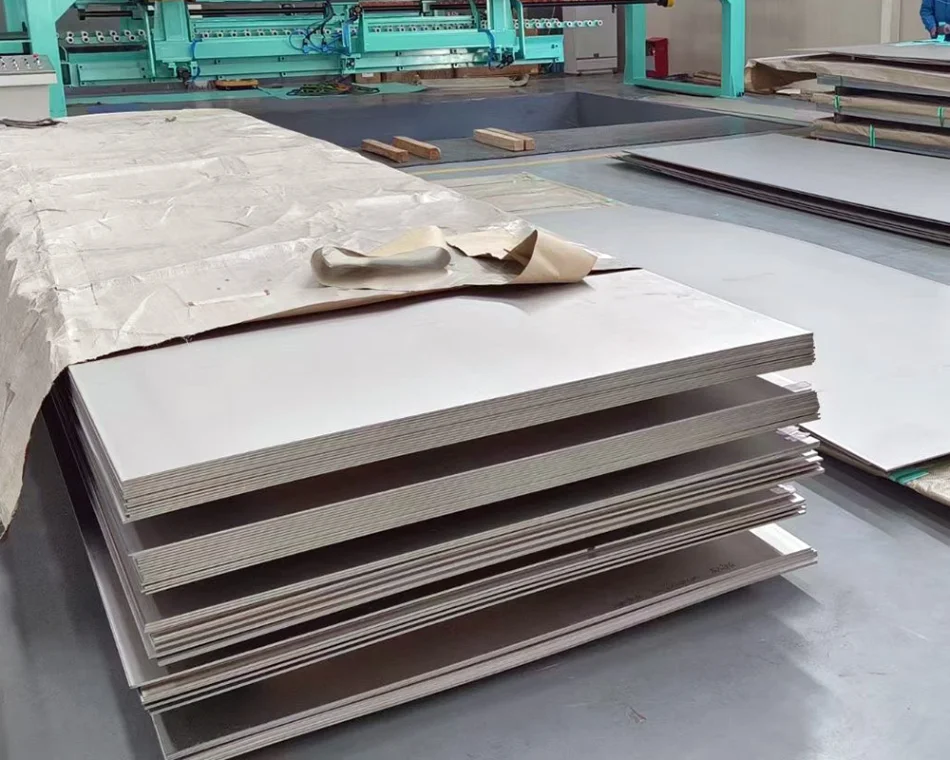

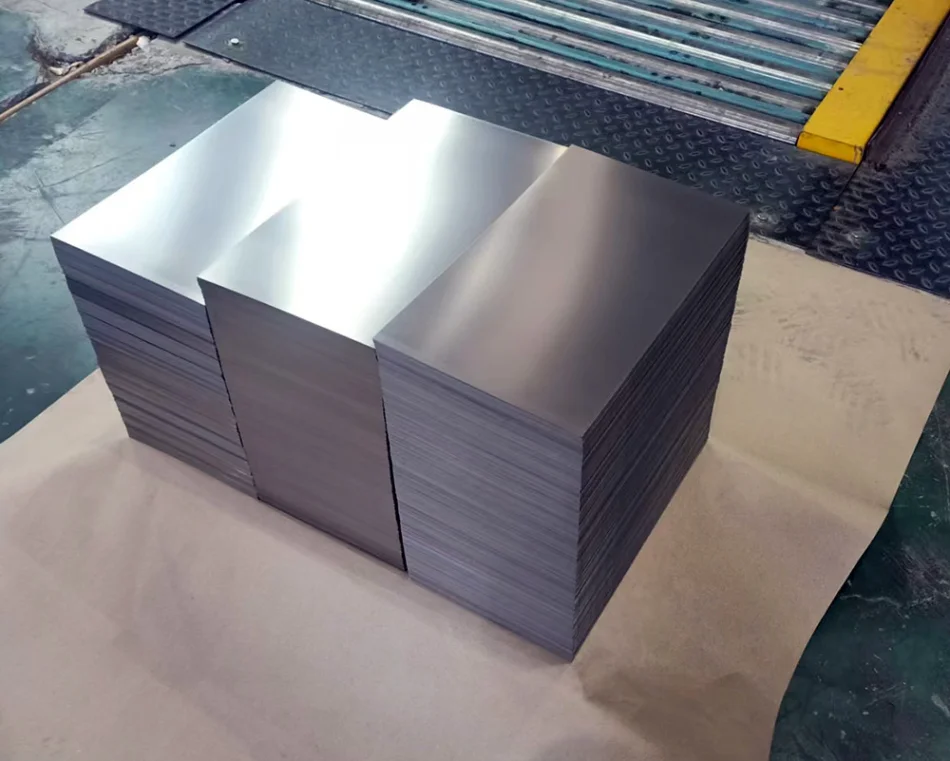

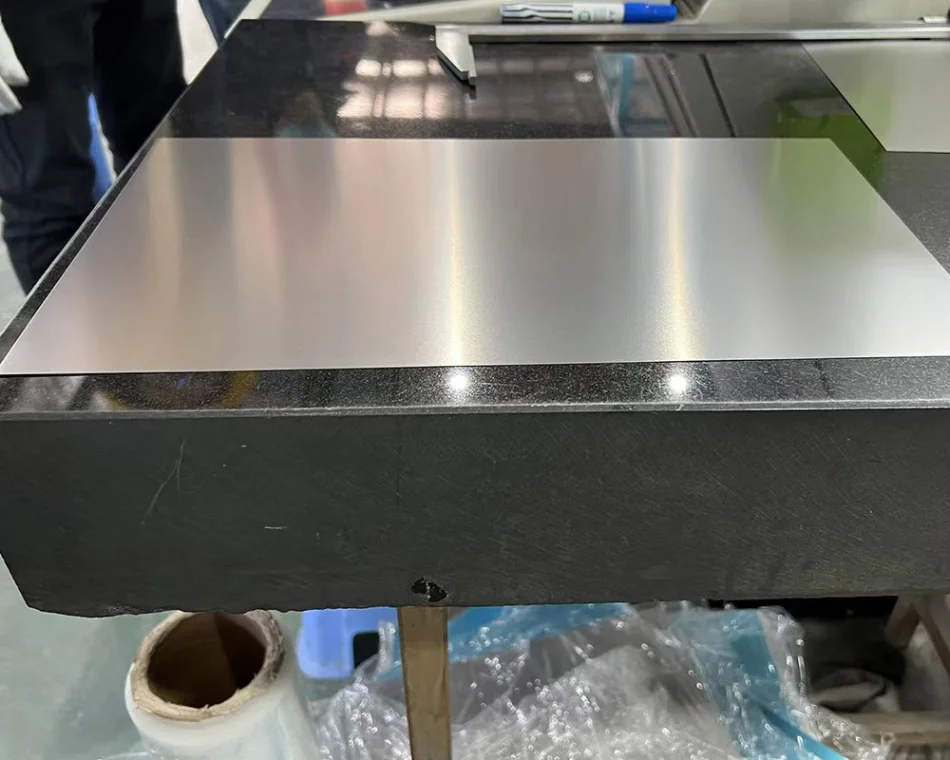

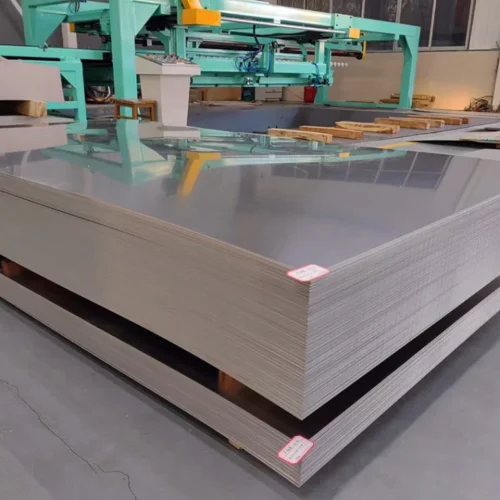

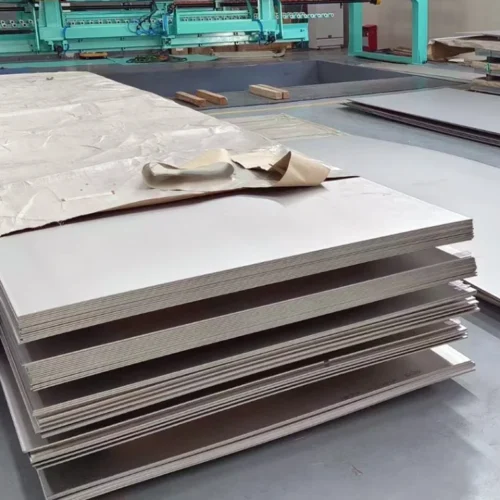

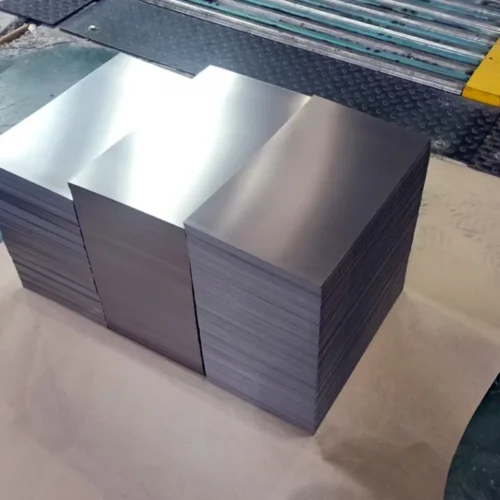

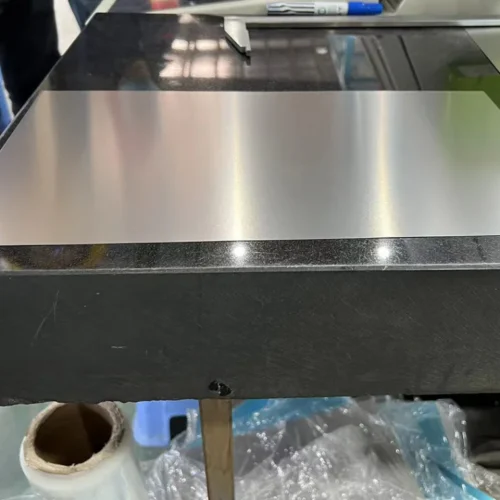

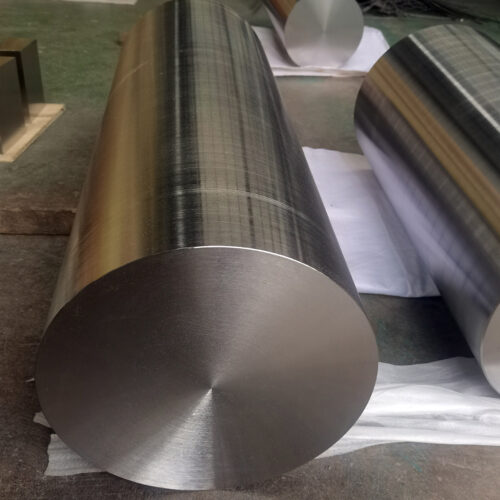

Titanium plates with a thickness greater than 3mm are typically hot rolled, while titanium sheets with a thickness of 3mm and below are produced by cold rolling. Hot-rolled plates typically undergo descaling process using a mixture of nitric acid (HNO3) and hydrofluoric acid (HF). As a result, pickling treatment enhances the cleanliness and uniformity of the surface, leading to homogeneous appearance and improved corrosion resistance performance. Cold-rolled sheets pass the titanium plates through a set of rollers at room temperature to gradually reduce its thickness. In contrast to plates, the thinner sheets have a natural metallic surface finish, exhibiting excellent smoothness, consistent surface quality and accurate tight tolerances.

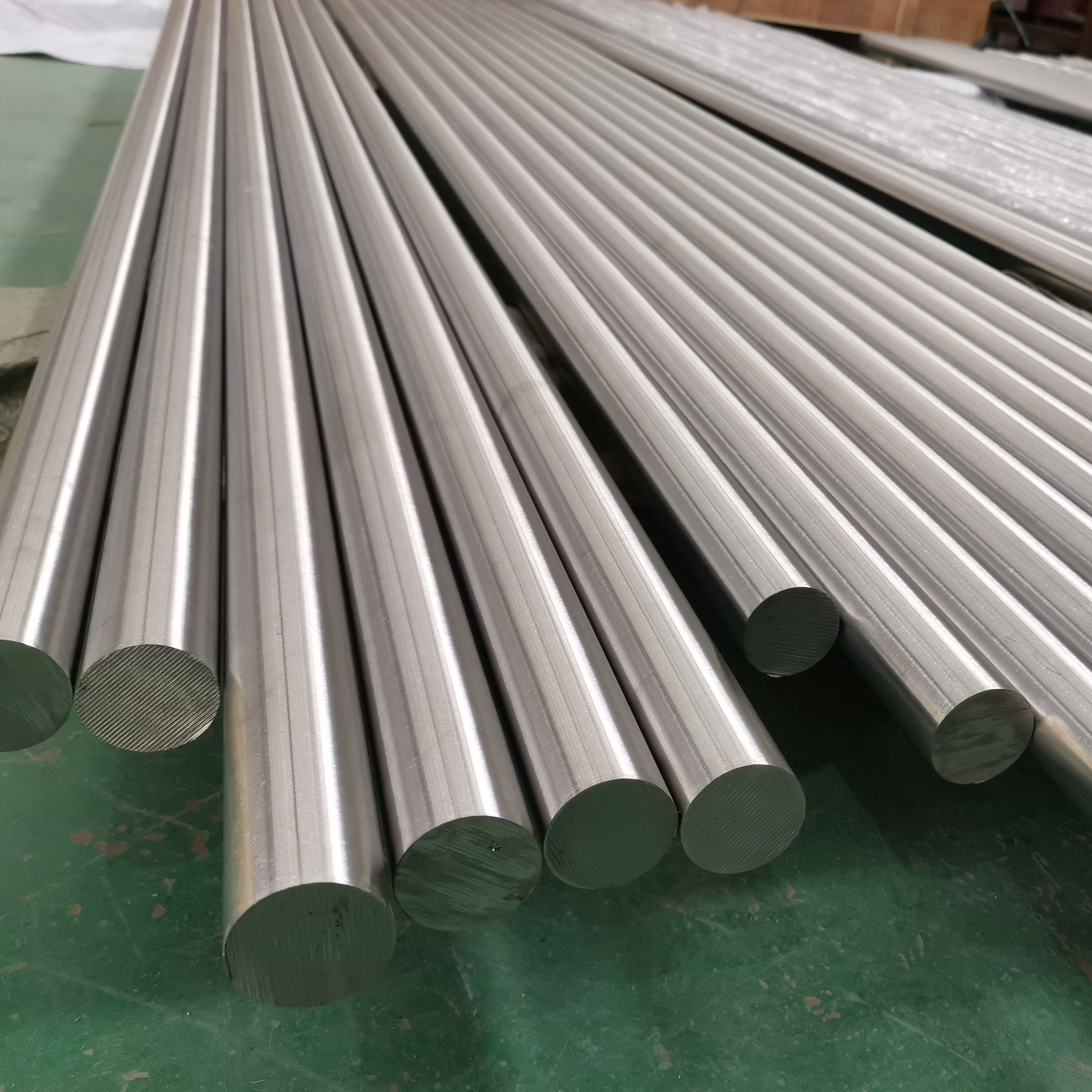

At our company, we offer a wide range of titanium grades and alloys to cater to various challenging applications and performance requirements. We provide commercially pure titanium as well as specific alloys such as Ti-6Al-4V (Grade 5), Ti-Pd (Grade 7), or Ti-0.3Mo-0.8Ni (Grade 12). These grades offer different characteristics and properties, allowing customers to choose the most suitable material for their projects.

In addition, we provide customization services to meet specific project requirements. Our services include cut-to-size options, PVC film coating for protection, and tailored marking for easy identification. We strive to deliver titanium plates and sheets that seamlessly match our customers’ specifications and applications.

Learn more about our Titanium Coils and Strips

Essentials and Specifications of Our Titanium Plates and Sheets

| Deformation process | Hot / cold rolled |

| Heat treatment | Annealed, Solution heat treated (and aged) |

| Surface condition | As cold-rolled, Hot-rolled and Pickled, Sandblasted |

| Size of plates | Thk 3-100 mm x W < 3000 mm x L |

| Size of sheets | Thk 0.5-3 mm x W <1500 x < 6000 mm |

| Tolerance | According to specification or order requirement |

| Custom-tailored service | Cut to size by shearing, EDM, waterjet or laser Packing paper wrapped or PVC thin film covered for protecting the surface Laser marking as per order requirement |

| Typical Specification | ASTM B265, ASME SB265 (Industrial) |

| AMS 4900, AMS 4901, AMS 4902, AMS 4911, AMS 4914 (Aerospace) | |

| MIL-T- 9046 (Defense) | |

| ASTM F67, ASTM F136, ISO 5832 (Medical) | |

| ♦ Other specifications are in accordance with specific alloy required |

Principal Inspections and Tests Required for Titanium Plates and Sheets

| Visual & Dimensional Inspection | |||

| Surface quality | Edges quality | Planarity | Tolerance |

| Mechanical Properties Test | |||

| Tensile strength | Yield strength | Elongation | Bending Test |

| Hardness test | Tensile at evaluated temperature | ||

| Chemical and Metallography Analysis | |||

| Chemical composition | Microstructure | Macrostructure | Grain size |

| • Inspection and Test executed according to specification or order

• Certificate EN 10204 3.1/3.2 |

|||