QUALITY CONTROL

QUALITY CONTROL

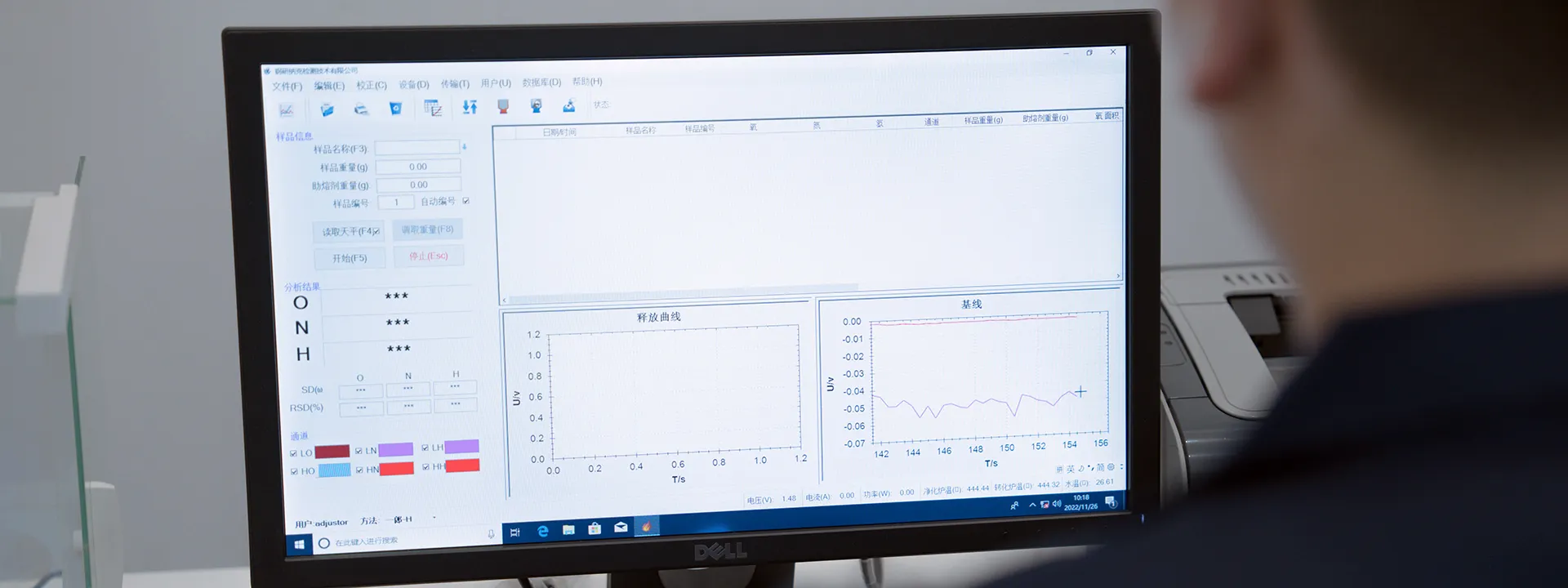

Exact process control is implemented from order placement and the receipt of materials right through to shipping. We have both heat number control and lot control in place to ensure total traceability. Furthermore, PMI tests (simplified chemical composition tests) are conducted on all material after receiving and before shipping to prevent material mix from entering or leaving the place.

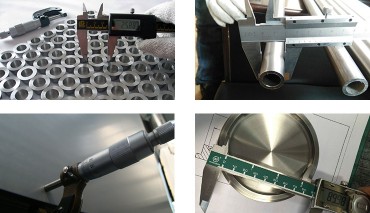

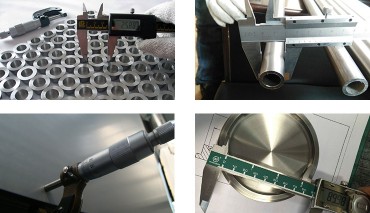

We inspect:

OD / ID / Thickness / Wall / Width / Length / Chamfer / Threads

Straightness / Planarity / Concentricity

RETI test the material according to standard typical or customer designated. We are able to provide traceable Testing Reports for:

– Chemical composition (ICP, GDMS, LECO)

– Mechanical properties (Universal)

– Microstructure, Grainsize (Metallographic microscope, SEM)

– Hardness, Density

To fully meet the needs of customers in various countries and industries, we only place orders for metal materials after having determined the details of specifications with steel mills. Receiving inspections of all the metal materials take place in accordance with ISO9001 to ensure the reliable quality. AS9120 certified metal materials are subject to stringent control to ensure quality.

AS9120 is a quality management system used in the aerospace industry, in which obviously safety and reliability are considered paramount. This standard applies to logistics providers involved in the supply chain of the aerospace industry as well as any related wholesale and retail companies.

Acquiring AS9120 certification has allowed us to provide “even more confidence” to our customers in addition to the strict lot and traceability control that they know we have long been committed to.

Titanium Products

Titanium Products

Titanium Alloys

Titanium Products

Titanium Products

Titanium Alloys

Titanium Products

Titanium Products

Titanium Alloys

Titanium Products

Titanium Products

Titanium Alloys

Titanium Products

Titanium Products

Titanium Alloys

Titanium Products

Titanium Products

Titanium Alloys

To fully meet the needs of customers in various countries and industries, we only place orders for metal materials after having determined the details of specifications with steel mills. Receiving inspections of all the metal materials take place in accordance with ISO9001 to ensure the reliable quality. AS9120 certified metal materials are subject to stringent control to ensure quality.

At [ Ridor Metals ], we value customer satisfaction and strive to provide the highest quality Molybdenum strips and foils. However, we understand that occasional issues or concerns may arise. We are committed to addressing any complaints promptly and offering appropriate compensation when necessary.

Customer Support: We have a dedicated customer support team ready to assist you with any complaints or issues you may have. You can reach out to us through various channels:

Provide detailed information about your complaint, including the product details, issue encountered, and any supporting evidence.

Our team will thoroughly investigate the complaint to understand the root cause and gather all relevant information.

We will work diligently to find a satisfactory solution to address your complaint. This may involve product replacement, refunds, or alternative arrangements.

We will keep you informed throughout the resolution process, providing regular updates on the progress made and expected timelines.