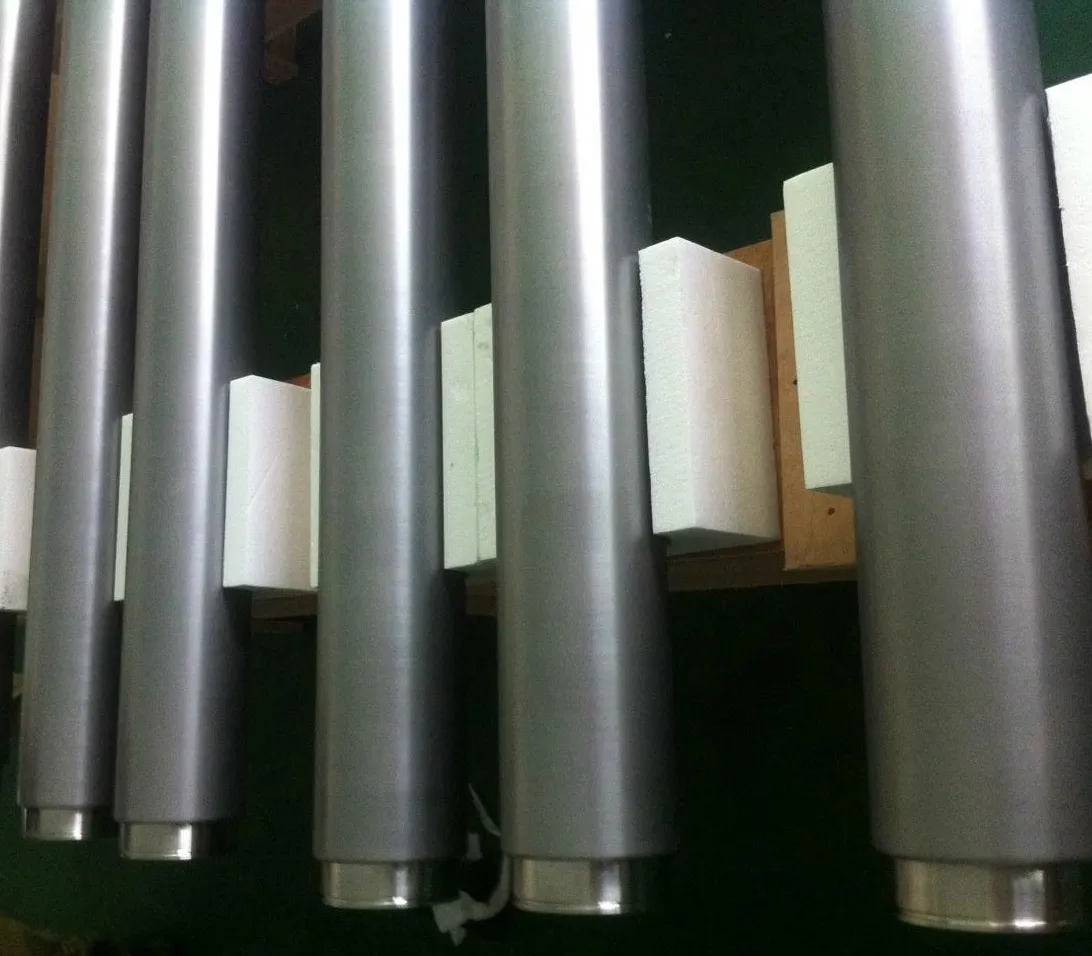

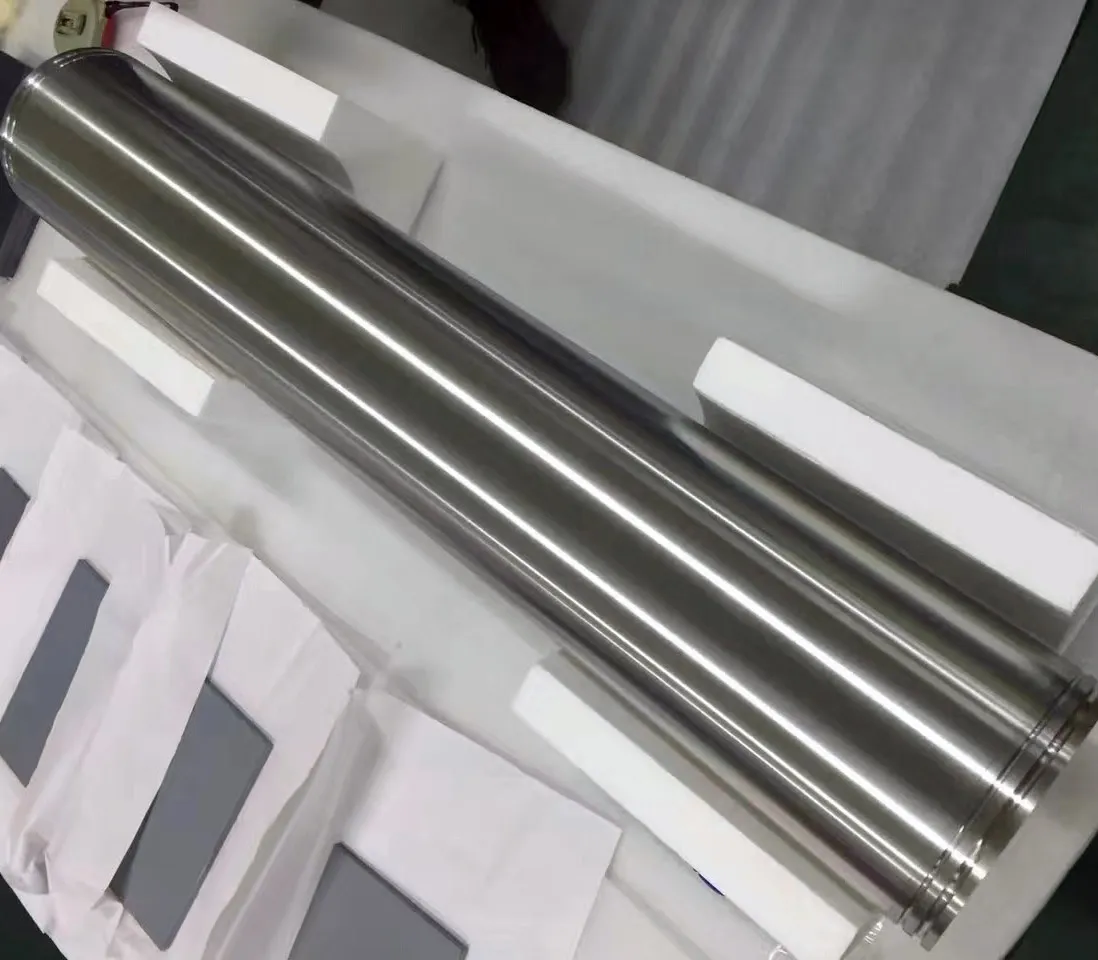

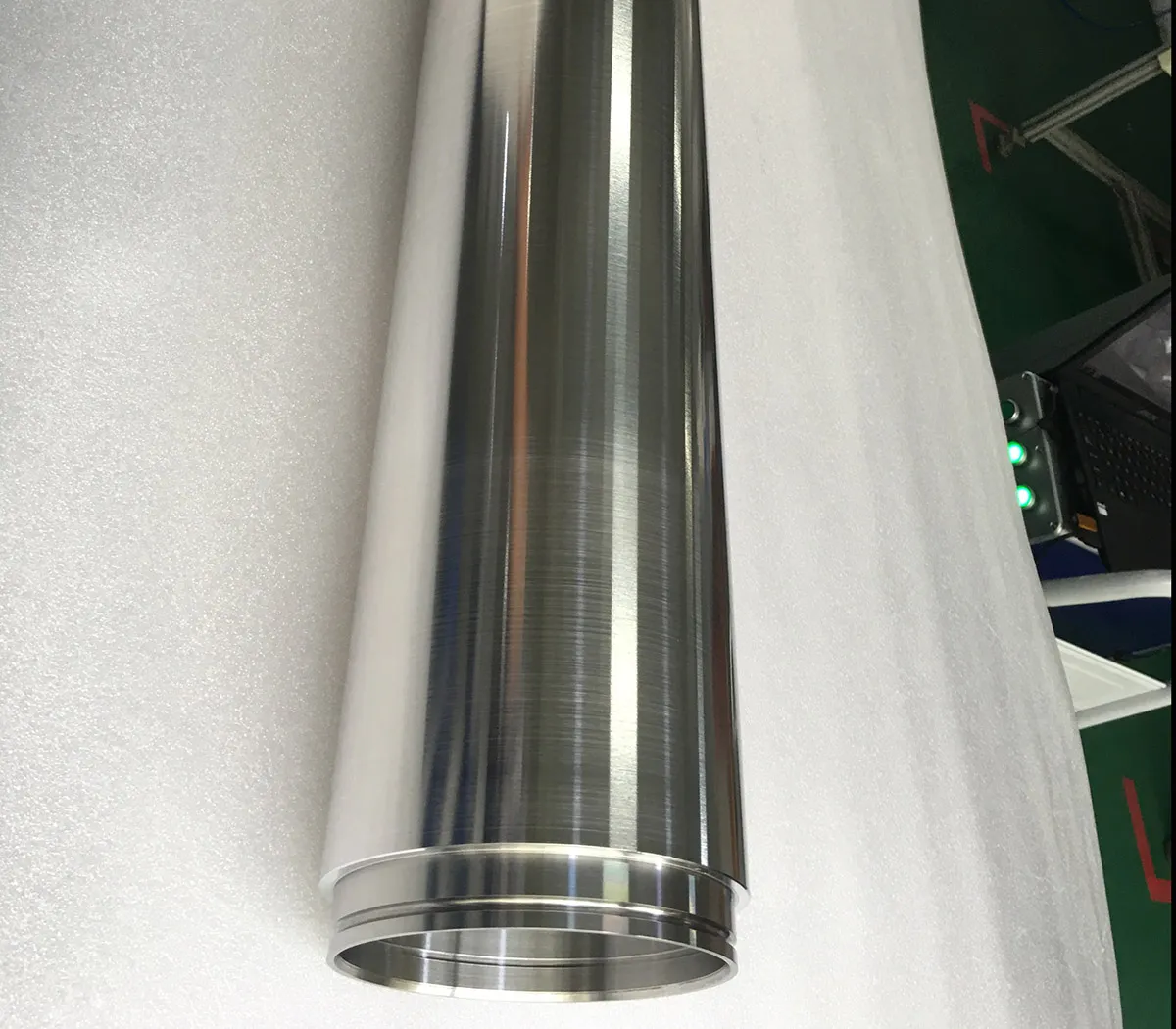

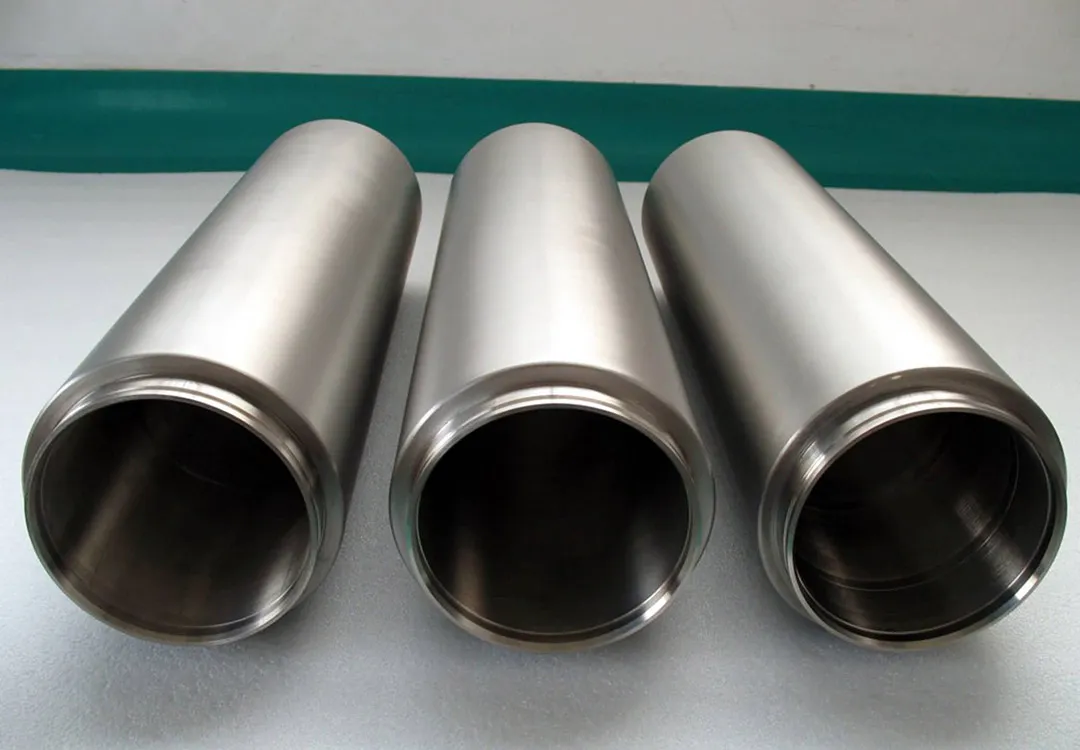

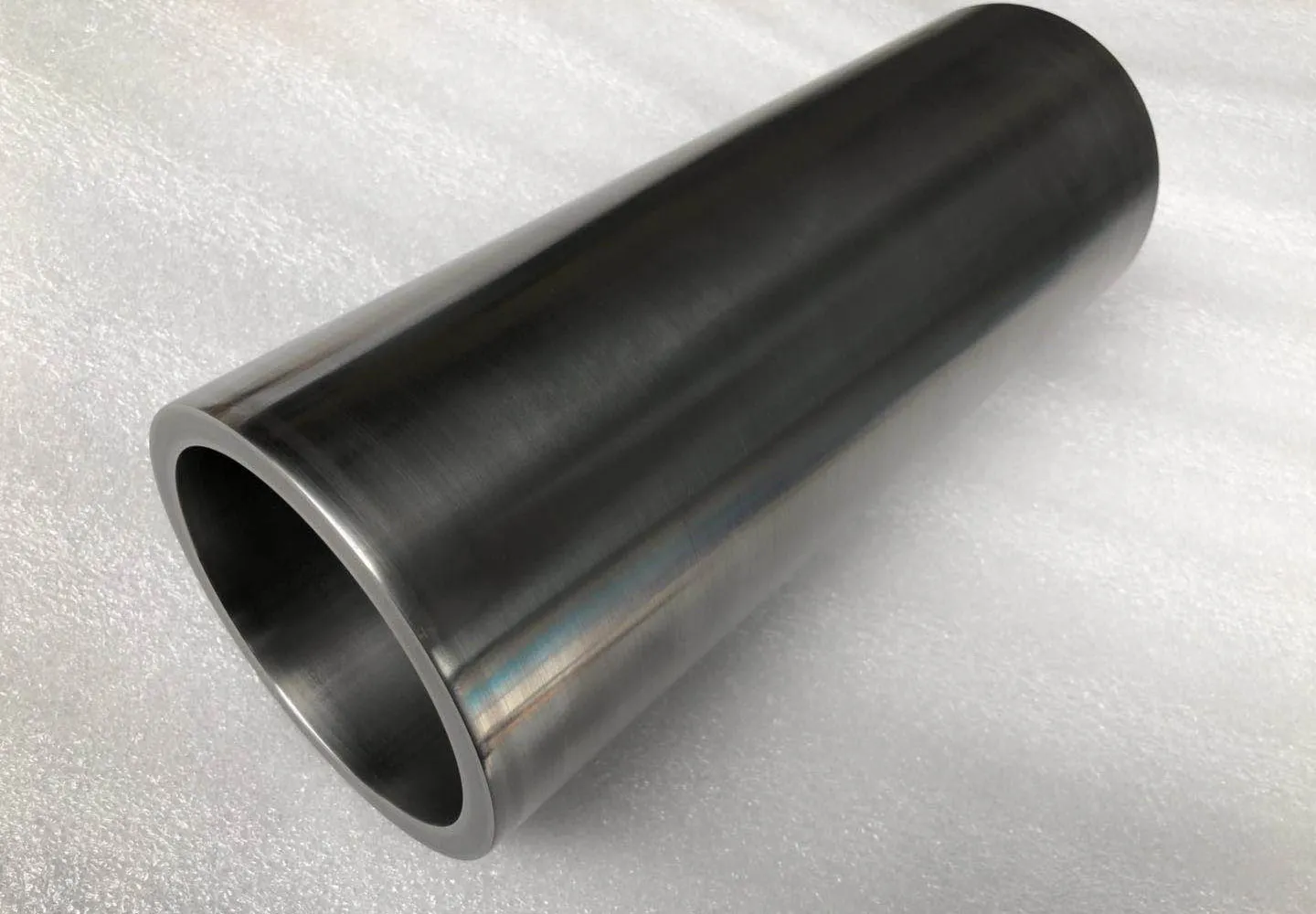

ROTATABLE SPUTTERING TARGETS

ROTATABLE SPUTTERING TARGETS

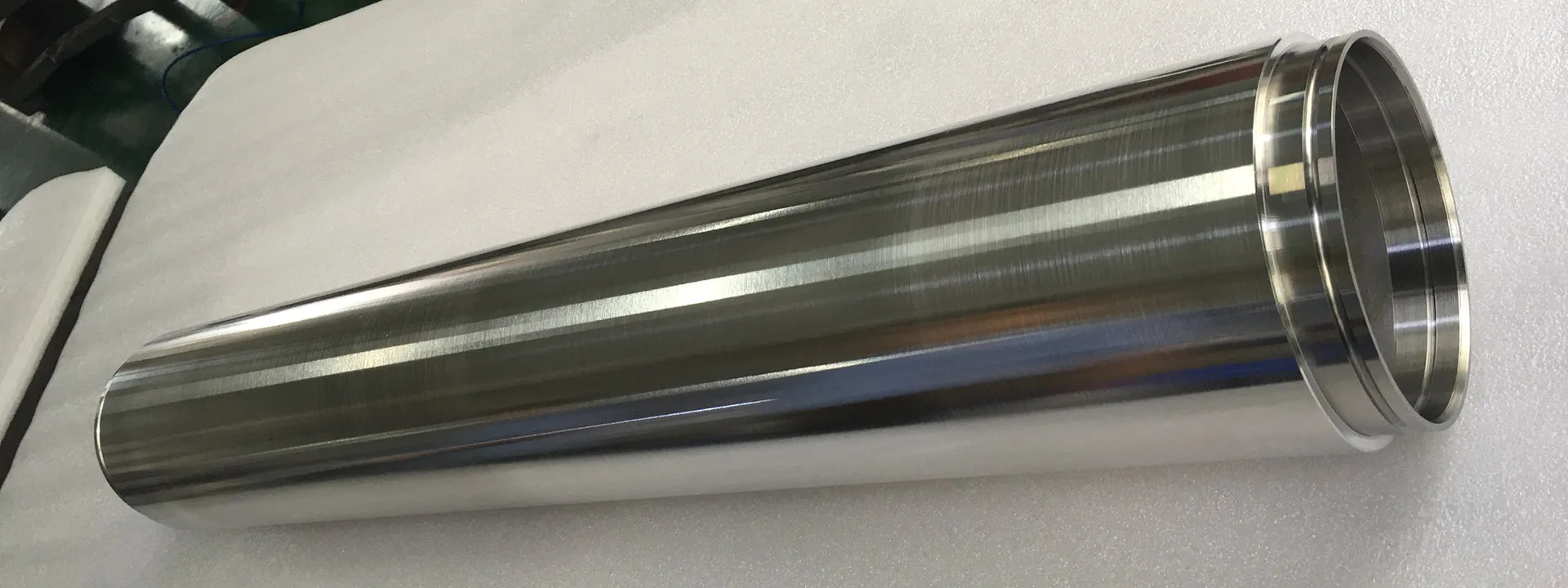

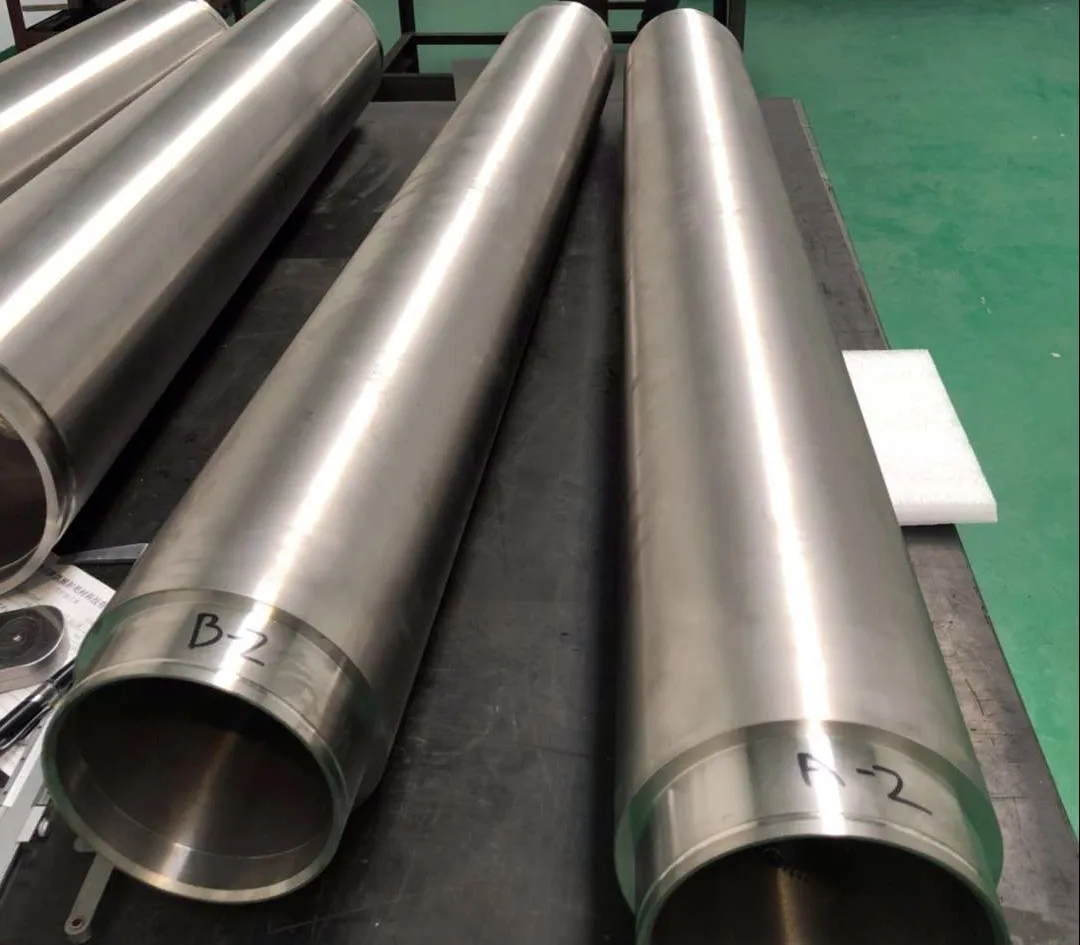

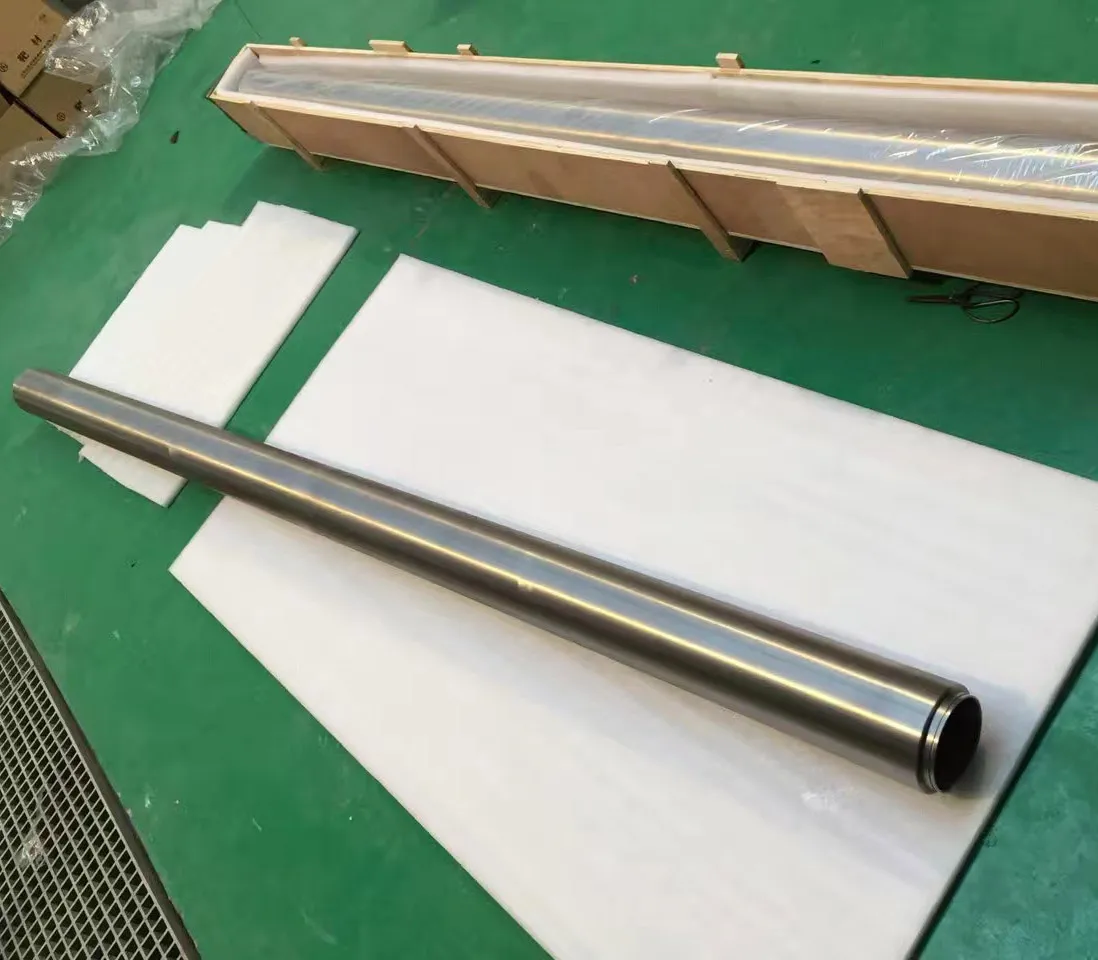

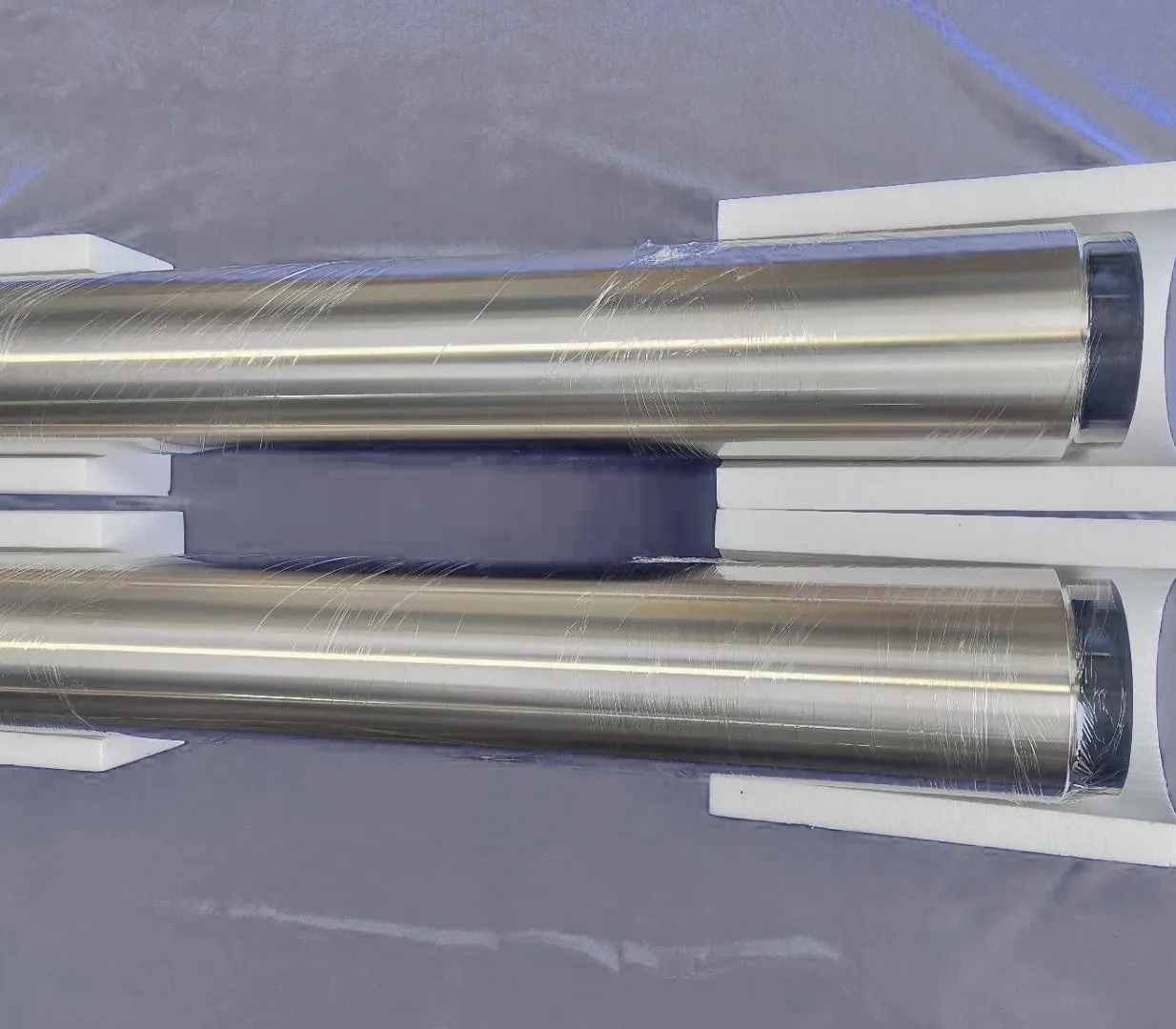

RETI specializes in the design and production of rotatable sputtering targets that include a variety of metals and alloys compatibly selected to meet the unique requirements of our clients.

We recognize that each project comes with its own set of challenges and specifications. RETI’s team of experienced engineers works closely with clients to provide tailor-made options that covering raw material melting process, deformation technique, composition and degas control, grain size, and other performance characteristics that be concerned.

Purity: 99.5%~99.995%

Melting: VAR

Forming: Extruding

Configuration: Monolithic

Bonding: None

Purity: 99.95%, 99.99%

Melting: EBM

Forming: Extruding

Configuration: Monolithic

Bonding: Optional

Purity: NbZr1 wt%, NbZr10 wt%

Melting: EBM

Forming: Extruding

Configuration: Monolithic

Bonding: Optional

Purity: 99.2%(Zr<2.5%), 99.95% (Zr<0.2%)

Melting: VAR

Forming: Extruding

Configuration: Monolithic

Bonding: None

Purity: 99.9%

Melting: EBM

Forming: Extruding

Configuration: Monolithic, Multiple sections

Bonding: Optional

Purity: 99.95%~99.9995%

Melting: VIM

Forming: Extruding

Configuration: Monolithic

Bonding: None

Purity: 99.95%

Melting: EBM

Forming: Extruding

Configuration: Monolithic

Bonding: Optional

Ratio: 93Ni:7V wt%

Melting: VIM

Forming: Extruding

Configuration: Monolithic, Multiple sections

Bonding: Optional

Purity: 99.95%~99.9995%

Melting: VIM

Forming: Extruding

Configuration: Monolithic

Bonding: None

Purity: 99.7%, 99.9%, 99.95%

Process: HIP

Relative density: 90%

Configuration: Monolithic, Multiple sections

Purity: 99.95%, 99.97%

Process: CIP+HIP+Sintering

Relative density: 95% min.

Configuration: Monolithic, Multiple sections

Purity: 99.95%

Process: CIP+HIP+Sintering

Relative density: 90%

Configuration: Monolithic, Multiple sections