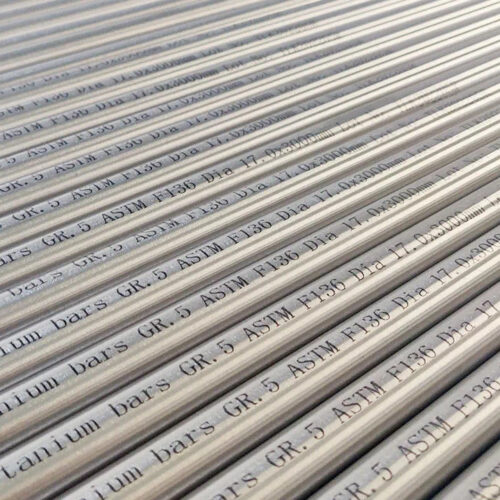

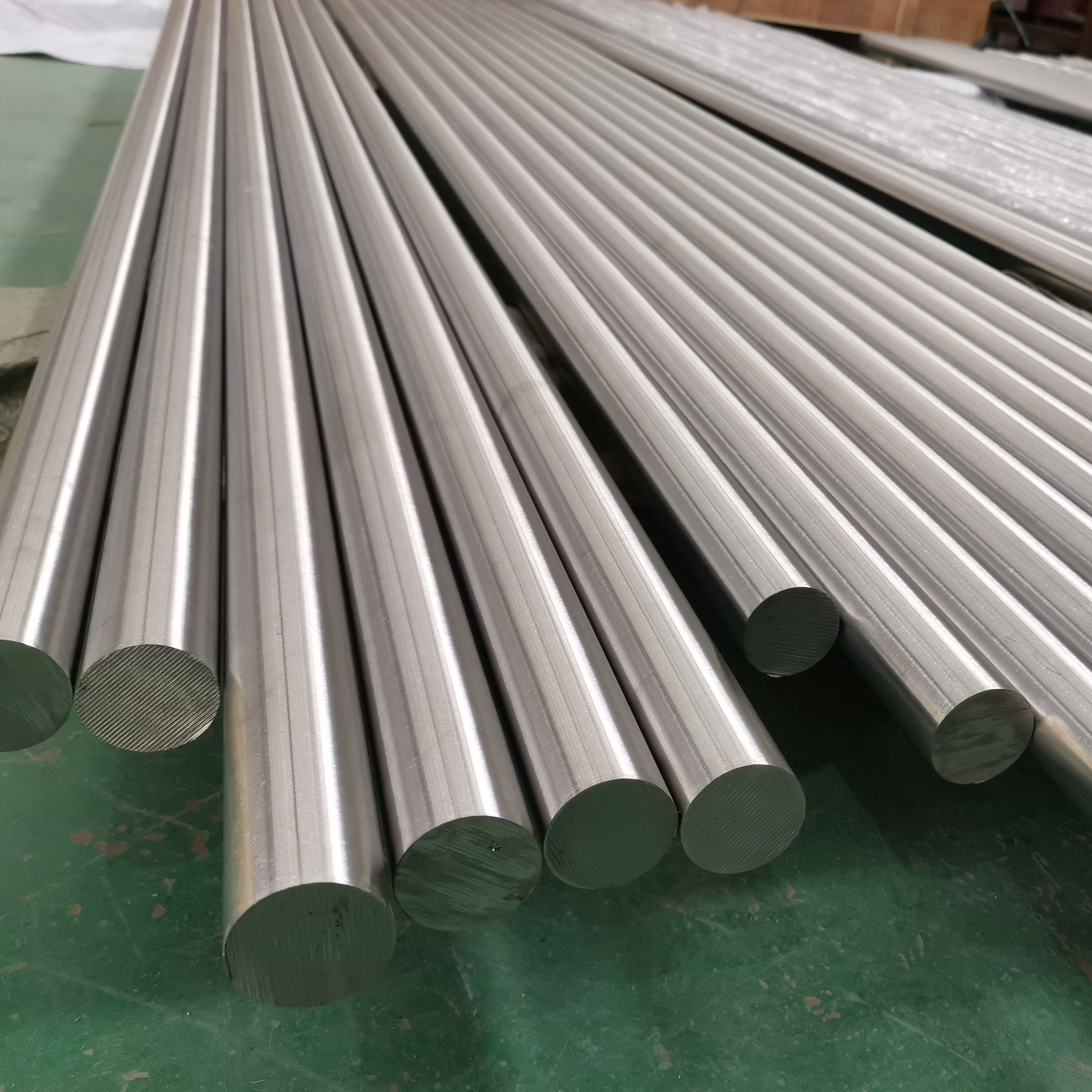

High Quality Raw Material Selection of Titanium Rods and Bars

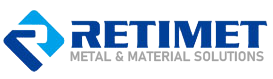

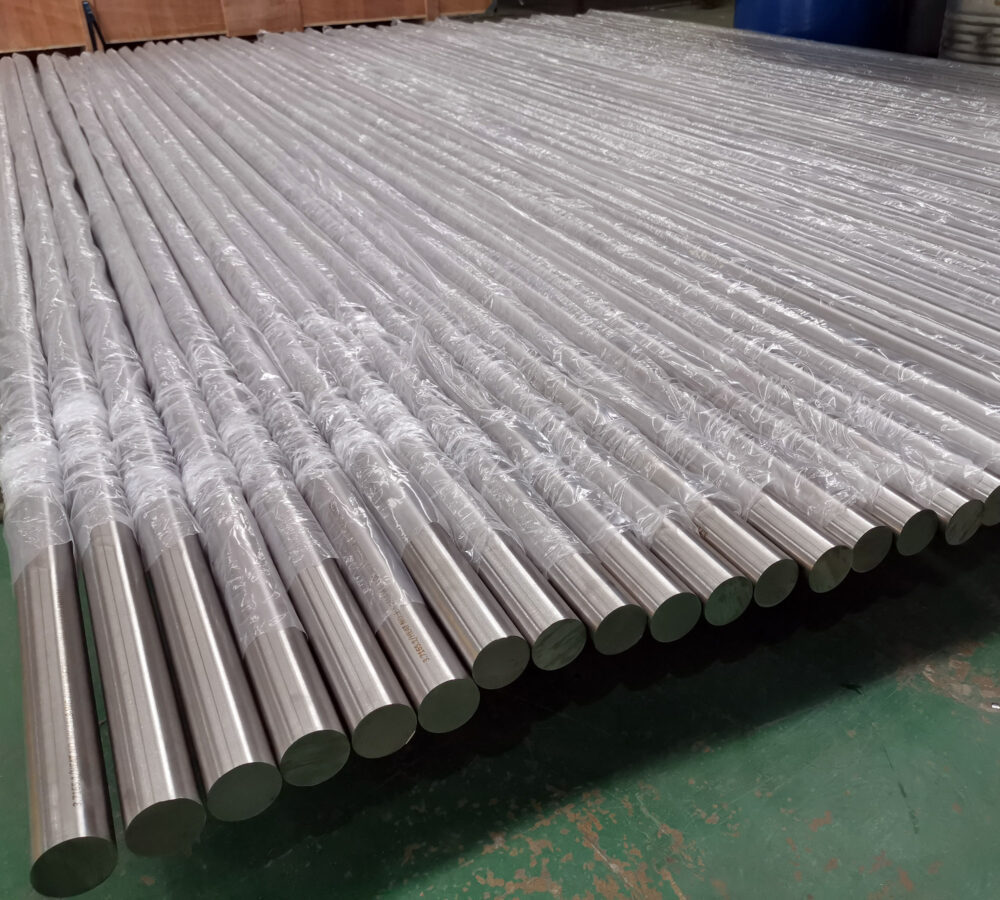

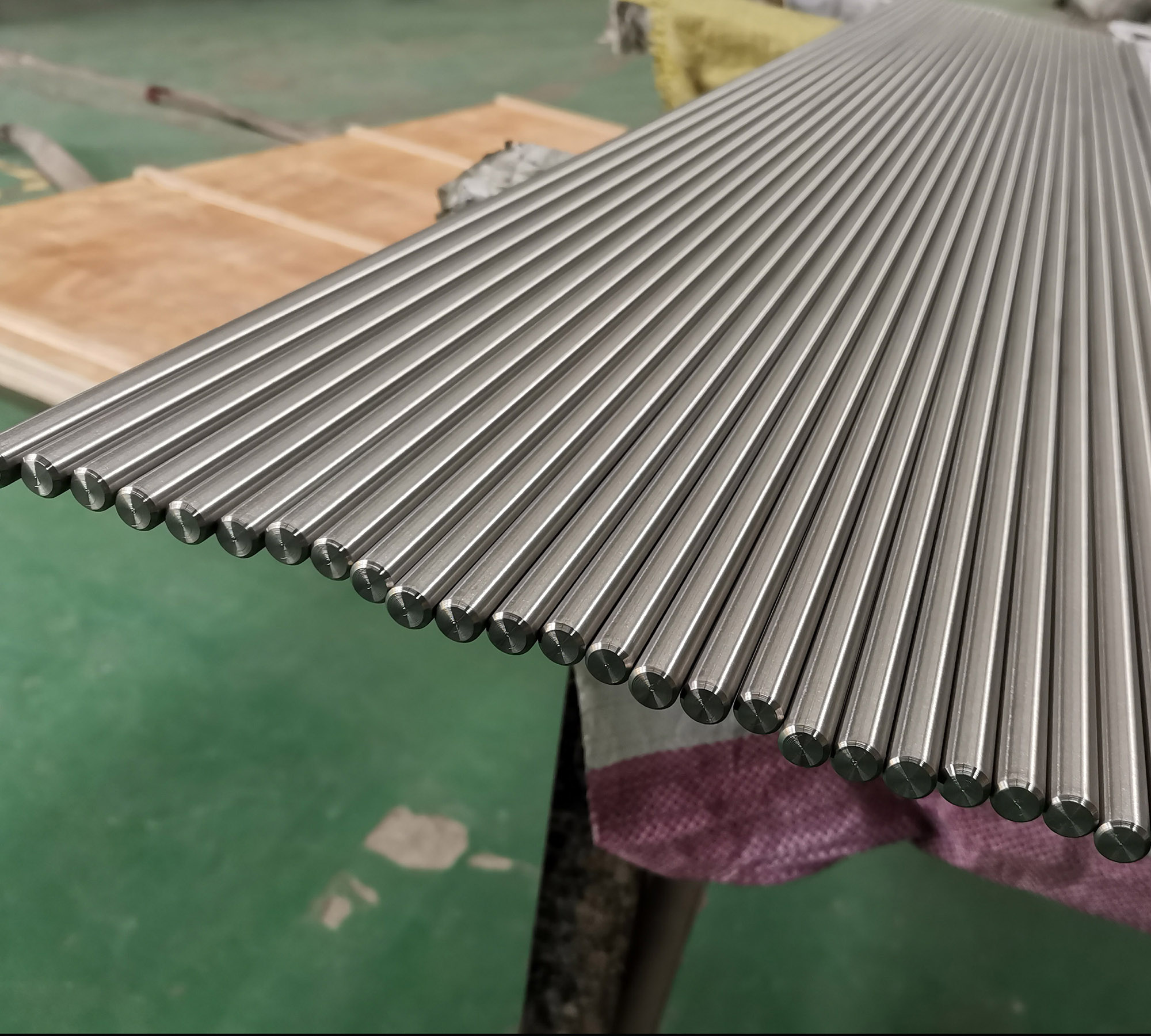

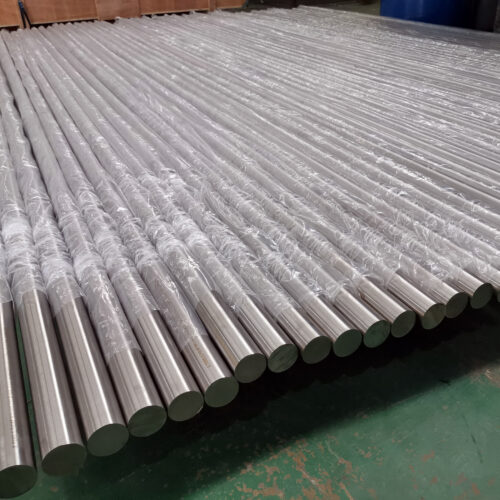

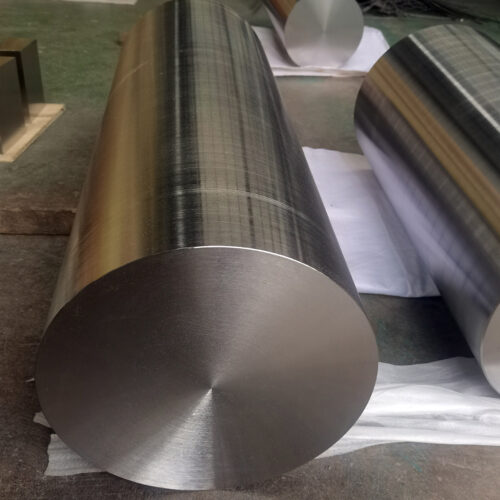

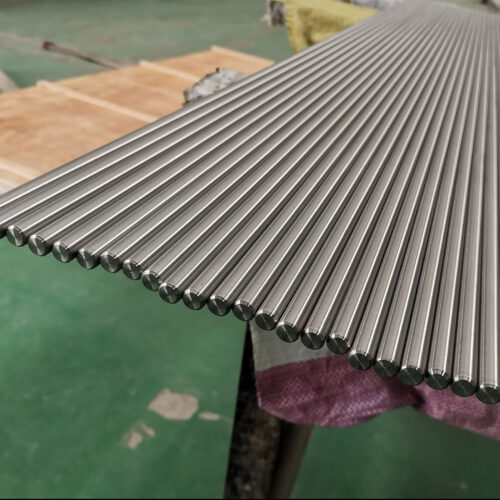

Manufactured using the highest-grade titanium raw material and advanced melting technology – VAR (Vacuum Arc Remelting) and EBCHM (Electron Beam Cold Hearth Melting), our titanium rods and bars offer exceptional strength, durability, biocompatibility, and outstanding performance in both high temperature and corrosive circumstance. Titanium Rods and Bars are accessible at us in a wide option of dimensions, specifications, and alloy grades to suit various requirements of our customers, from chemical, automobile to aerospace, medical and other general industrial sectors.

Description and Specification of Our Titanium Rods and Bars

| Melting method | VAR, EBCHM |

| Deformation process | Forging, rolling, drawing, swaging |

| Heat treatment | Annealed, Solution heat treated (and aged) |

| Surface finish | Turned, ground or polished |

| Diameter of round rod | 2 mm and above |

| Diameter tolerance | h6 to h11 |

| Length | Up to 6000 mm |

| Length tolerance | In accordance with specification or order |

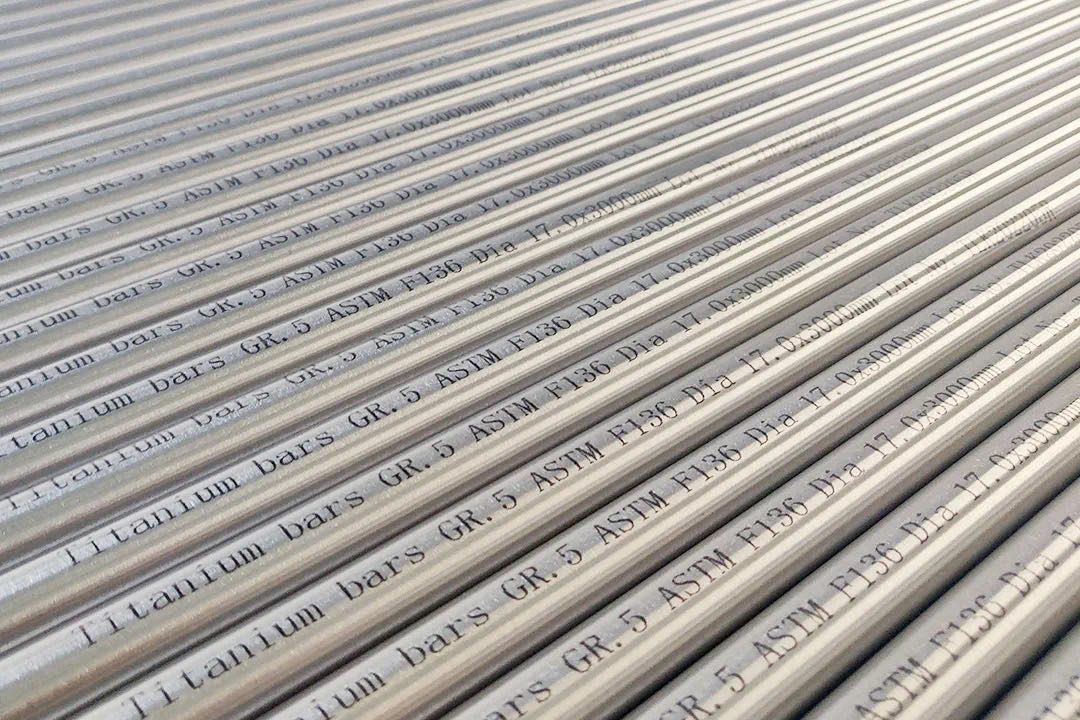

| Chamfer and marking | Chamfer and mark as per order request |

| Non-round section | Hexagonal bar, Rectangular bar, Flat bar, Square bar |

| Typical Specification | ASTM B348, ASME SB348 (Industrial) |

| AMS 4920, AMS 4921, AMS 4928, AMS 4965, AMS 4975 (Aerospace) | |

| MIL-T-9046 (Military) | |

| ASTM F67, ASTM F136, ASTM F1295, ISO 5832-2,3,11 (Medical) | |

| • Other specifications coincide with specific alloy requested |

Strength of Our Titanium Rods and Bars for Aerospace and Medical

Reliability and safety are the most important factors ought to be considered when titanium comes into the application for aerospace and medical realms. With our extensive know-how and over 15 years of experience in the field, we are committed to assuring our customers the highest standards of reliability and satisfaction, with our titanium rods and bars Ti-6Al-4V, Ti-6Al-4V ELI, Ti-6242, etc.

- Optical inspection for surface flaws

- Diameter measured by infrared gauge

- NDT Ultrasonic test per AMS 2631F, class AA, A1, A

- Microstructure per ETTC, A1-A10

- Grain size per ASTM E112, G<6

- Enhanced tensile strength by means of solution heat treating, aging, precipitating

Critical Inspections and Tests

| Visual & Dimensional Inspection | |||||

| Surface condition | Surface roughness | Marking quality | Diameter tolerance | ||

| Sectional tolerance | Length tolerance | Straightness | Chamfer tolerance | ||

| Mechanical Properties Test | |||||

| Tensile strength | Yield strength | Elongation | Reduction of area | ||

| Bending test | Hardness test | Creep strength | Fracture toughness | ||

| Fatigue strength | Impact toughness | ||||

| Chemical and Metallography Analysis | |||||

| Chemical composition | Microstructure | Macrostructure | Grain size determination | ||

| Non-destructive Test | |||||

| Ultrasonic | Eddy Current | Radiography (X-ray) | |||

| • Inspection and Test are executed according to specification or order

• Certificate EN 10204 3.1/3.2 |

|||||