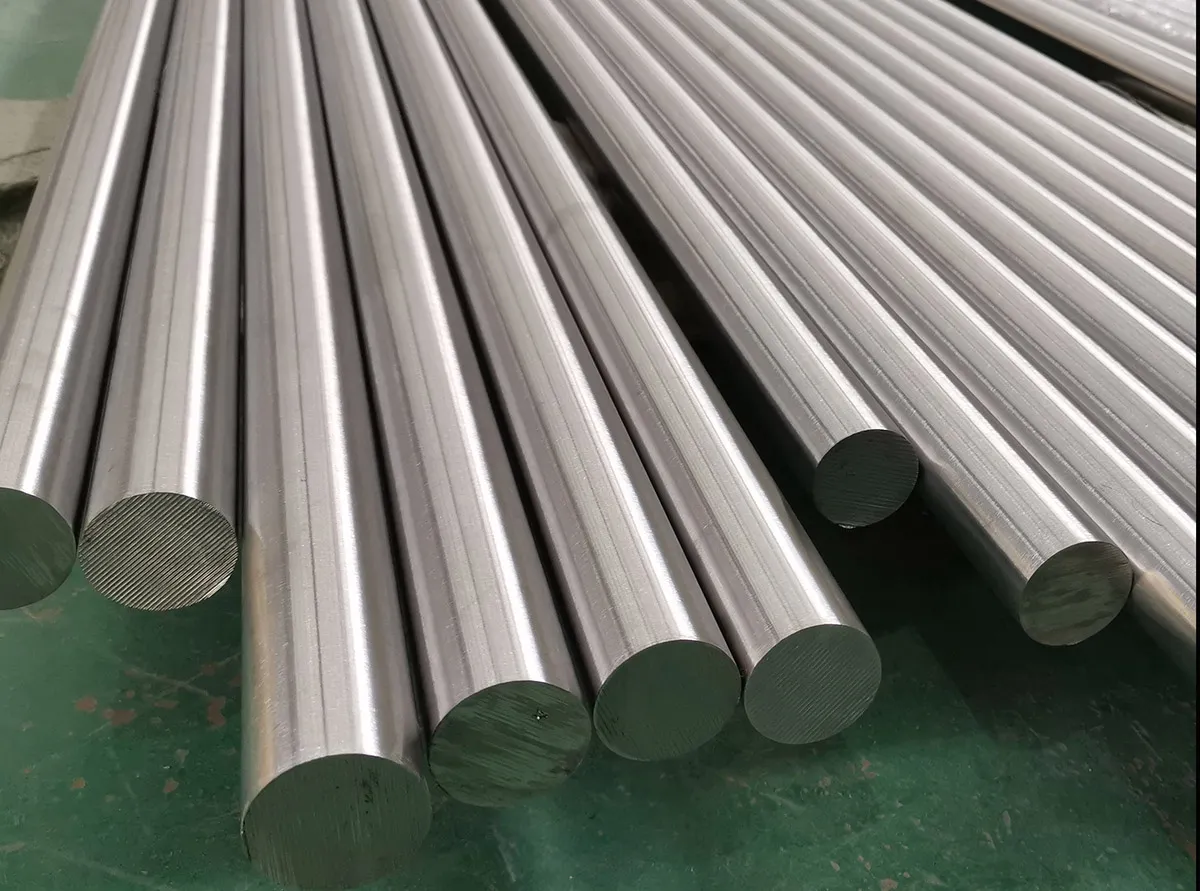

Recycled Metal Scraps

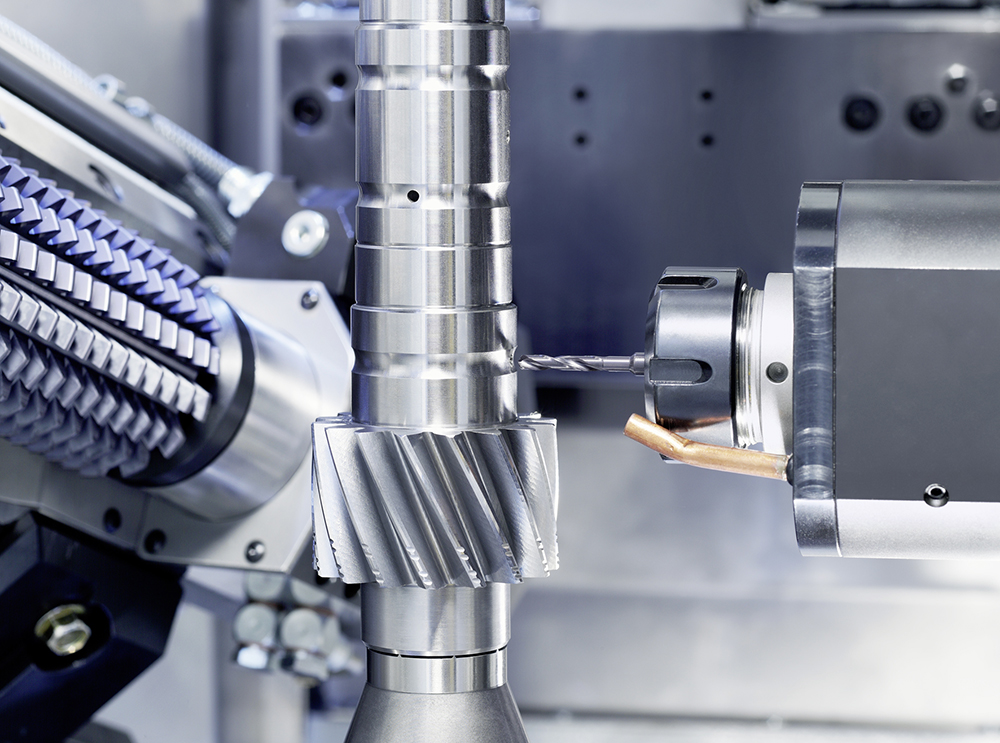

RETI back up global scrap purchasing companies by offering various refractory metals, including Tungsten, Molybdenum, Tantalum, Niobium, Zirconium and Titanium. We are dedicated to ensuring swift and efficient delivery, especially for bulk quantities demand.

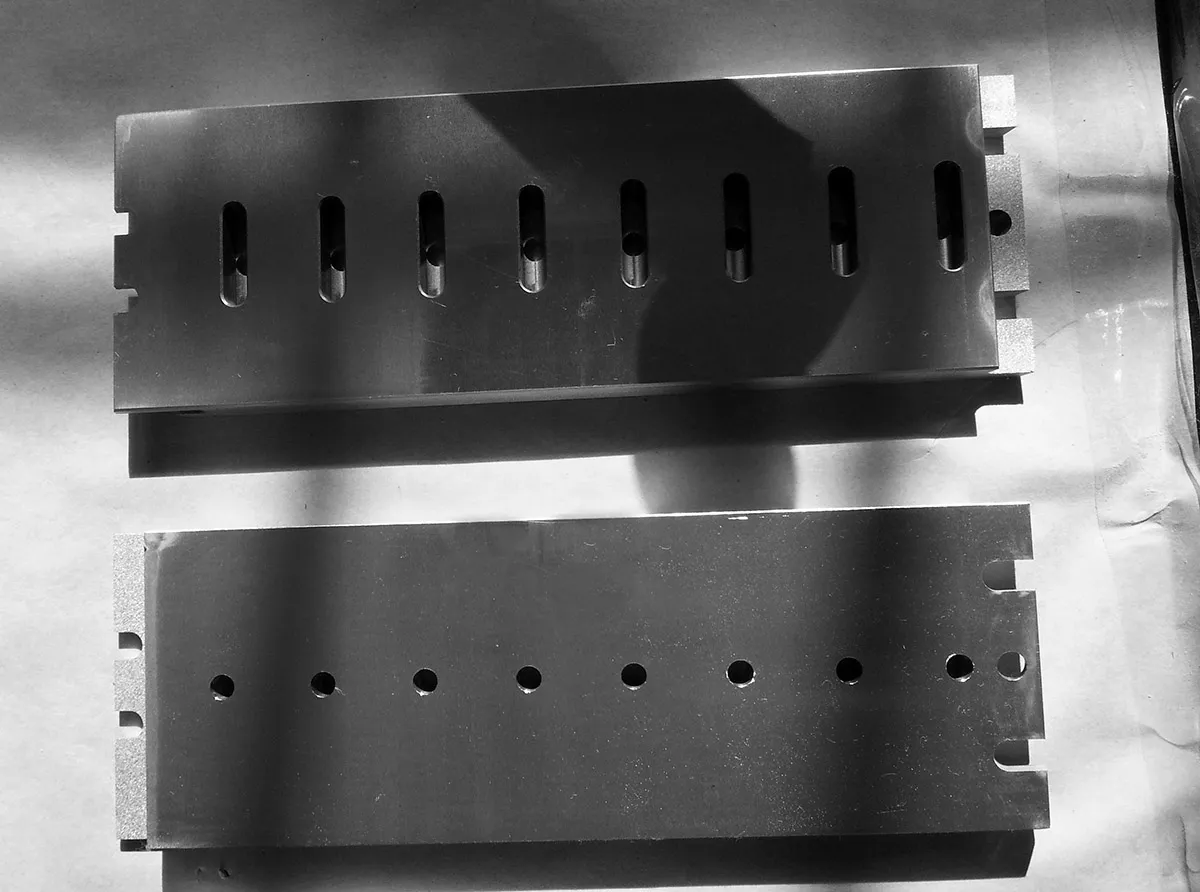

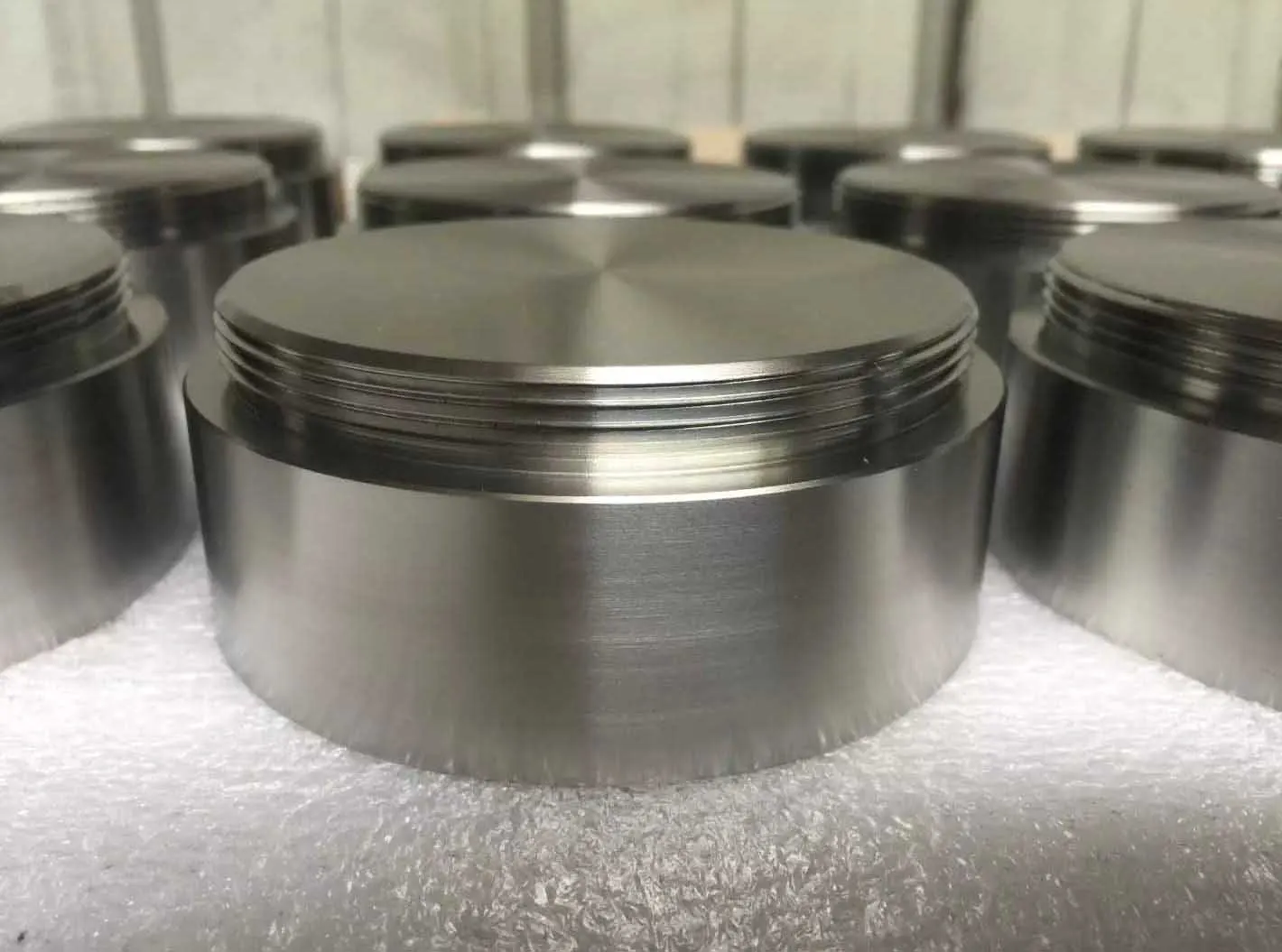

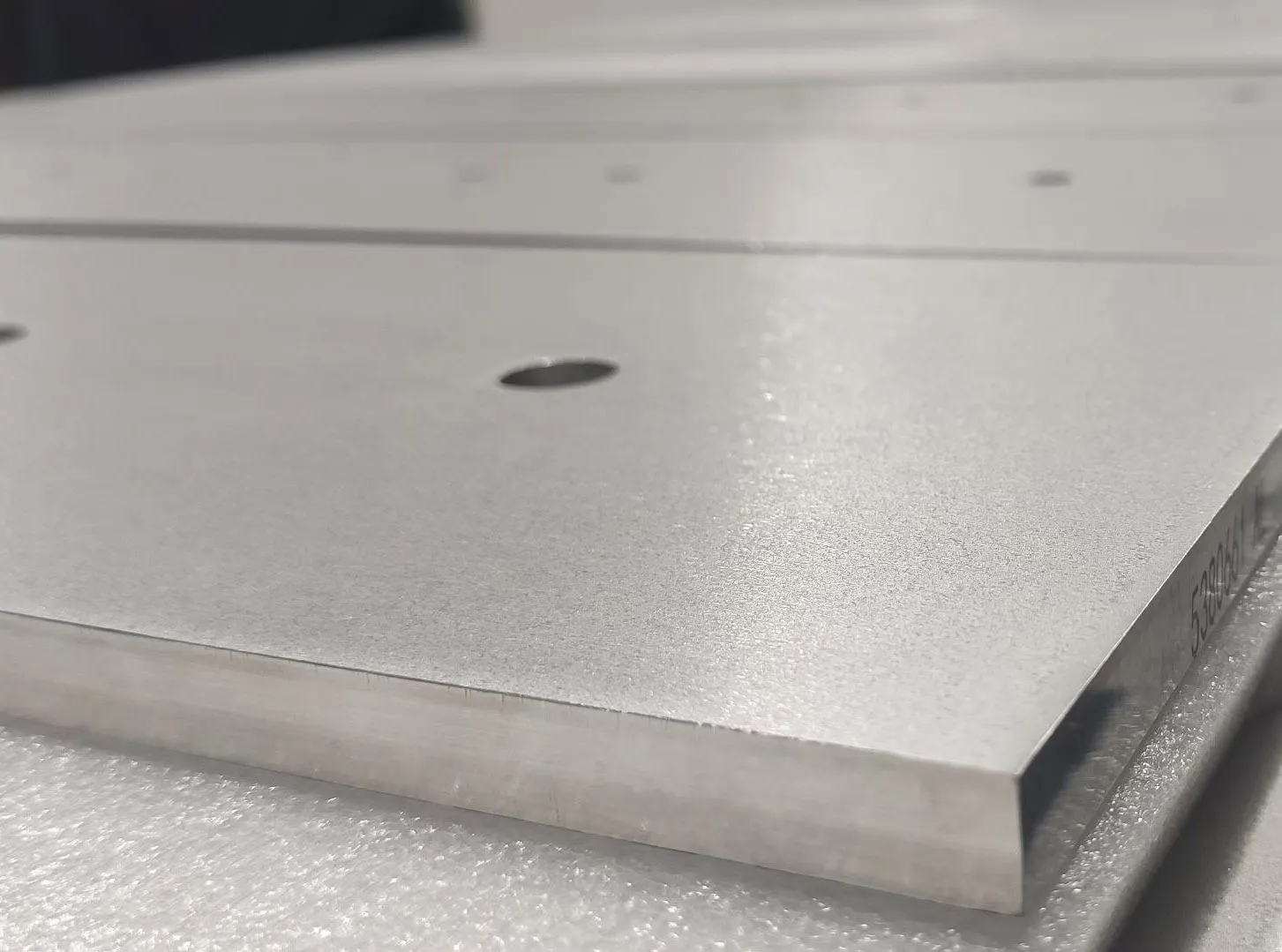

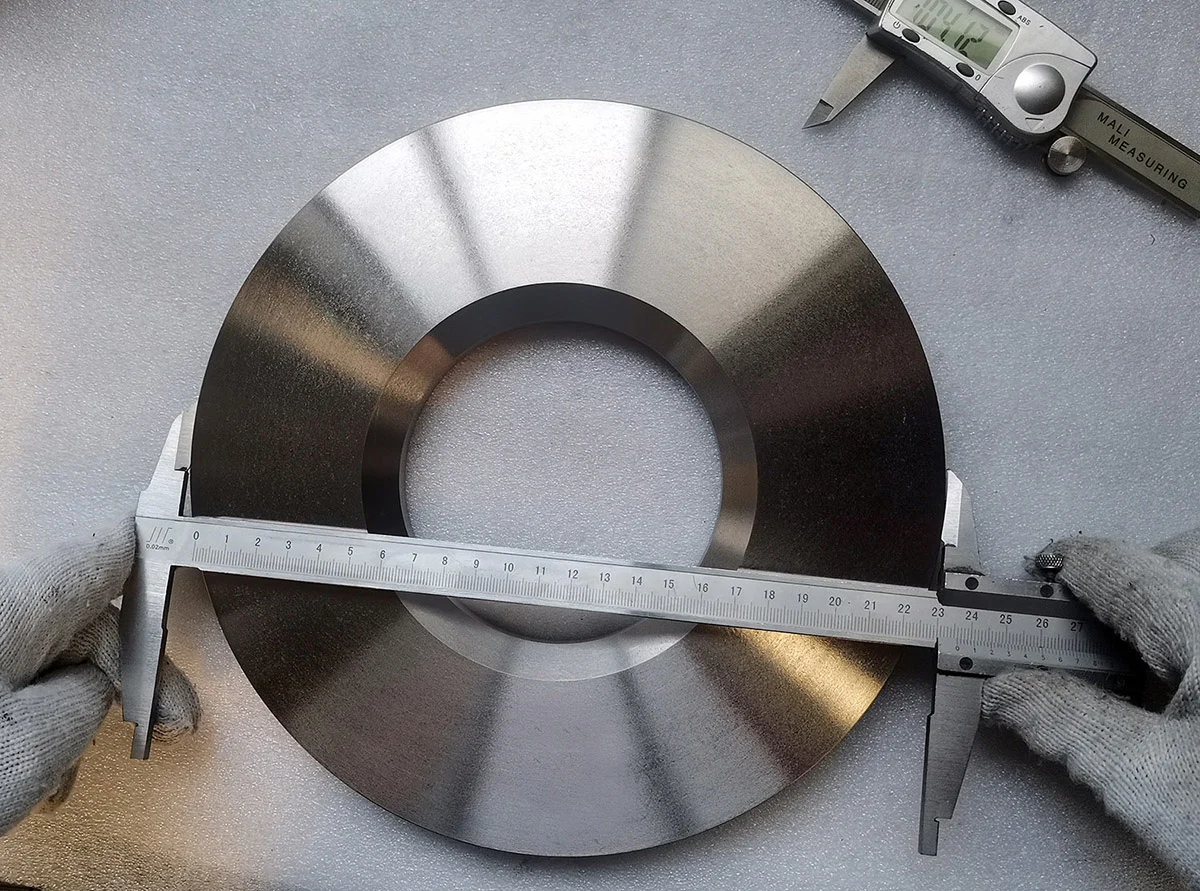

Our self inventory and well-connected sourcing network aid us to access and acquire scrap metals include but not limited to used sputtering target, plate, sheet, clip, foil, disc, bar, electrode, solid, chunk, tube, and the like. Wou can select and categorize scrap materials based on customer requirements.

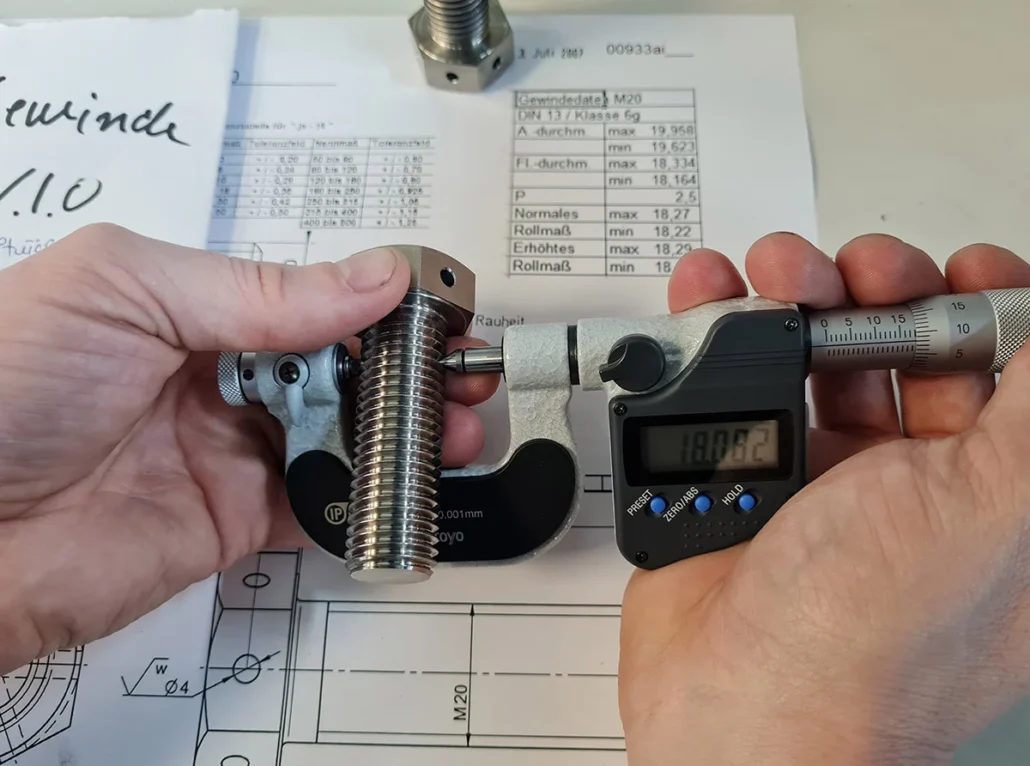

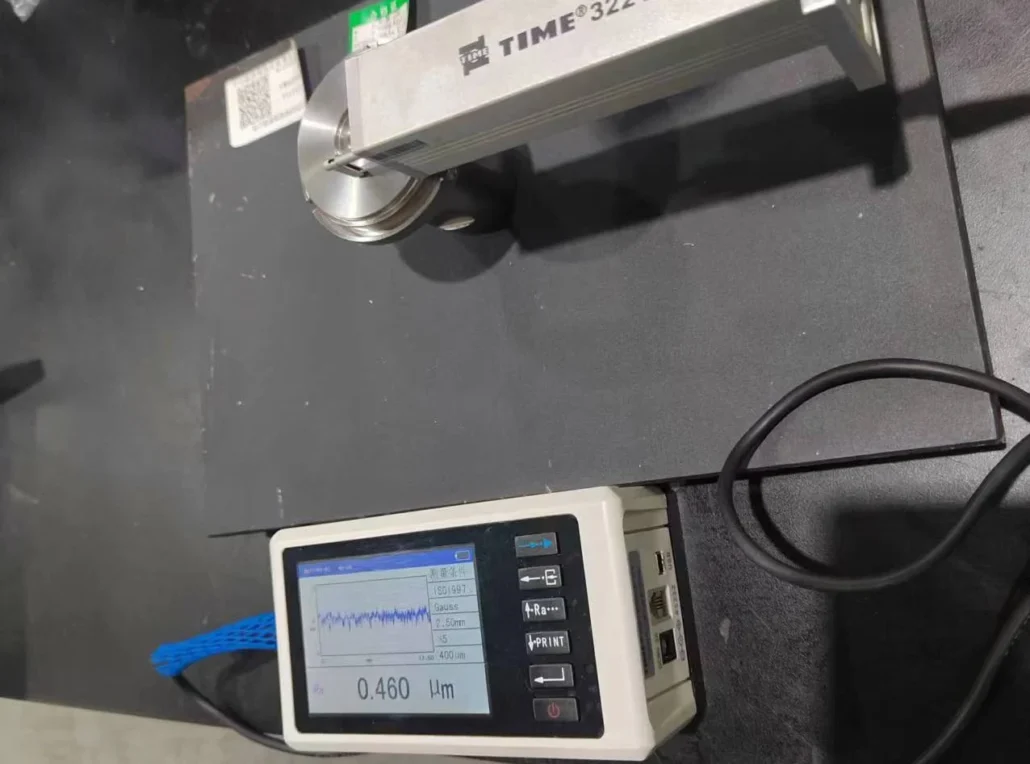

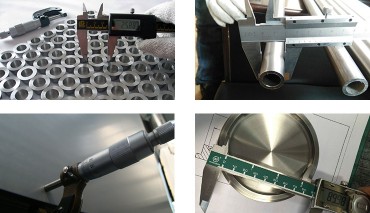

Each batch of scraps will be sorted manually, inspected visually and tested by XRF before packaging and shipping.