The characteristics of alloy grades

-

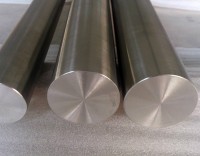

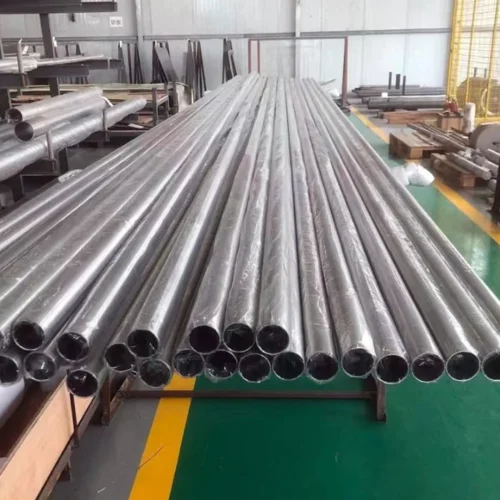

Superior Strength and Stiffness: Titanium alloys possess impressive strength and stiffness, allowing them to withstand heavy loads and provide structural integrity. This makes them ideal for applications in aerospace, automotive, and sports equipment industries where lightweight materials with high strength are required.

-

Outstanding Biocompatibility: Titanium alloys have excellent biocompatibility, meaning they are well-tolerated by the human body and do not elicit adverse reactions. This property makes them highly suitable for medical implants, such as dental implants, orthopedic implants, and surgical instruments, where biocompatibility and long-term performance are crucial.

Properties of alloy grades (composition, mechanical properties)

| Alloy Grade | Composition | Ultimate Tensile Strength | Yield Strength | Elongation |

|---|---|---|---|---|

| Grade 1 | Pure titanium | 240 MPa | 170 MPa | 24% |

| Grade 2 | Pure titanium | 345 MPa | 275 MPa | 20% |

| Grade 5 | 90% Ti, 6% Al, 4% V | 895 MPa | 828 MPa | 10% |

| Grade 9 | 95.5% Ti, 3% Al, 2.5% V | 620 MPa | 483 MPa | 15% |

| Grade 12 | 88% Ti, 0.3% Mo, 0.8% Ni | 483 MPa | 345 MPa | 18% |

| Grade 23 | 90% Ti, 6% Al, 4% V (ELI) | 860 MPa | 795 MPa | 10% |

| Grade 7 | 89.5% Ti, 0.2% Pd | 345 MPa | 275 MPa | 20% |

| Grade 23 | 90% Ti, 6% Al, 7% Nb (ELI) | 860 MPa | 795 MPa | 10% |