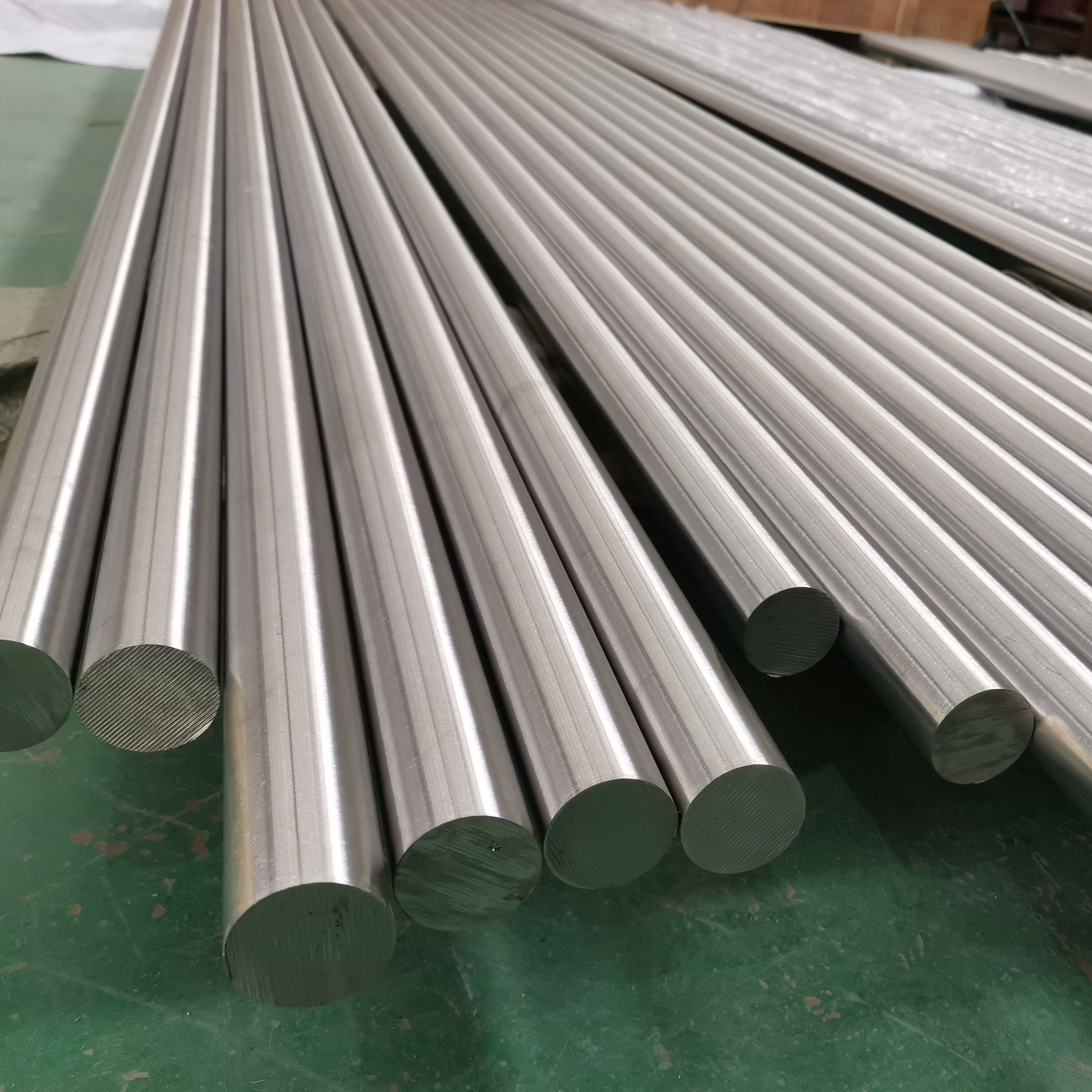

High-strength Titanium Alloy Most Widely Used

Titanium Grade 5, also known as Ti-6Al-4V, is the most popular and widely used titanium alloy. It is composed of approximately 90% titanium, 6% aluminum, and 4% vanadium. This alloy offers an excellent combination of high strength, low weight, and exceptional corrosion resistance.

One of the key advantages of Titanium Grade 5 is its remarkable strength. It provides a tensile strength of around 950-1250 MPa and a yield strength of approximately 850-1000 MPa. This high strength and its impressive strength-to-weight ratio makes Grade 5 suitable for applications where weight reduction and durability are essential, such as aerospace components, automotive parts, and marine engineering components.

In addition to its superior strength performance, Titanium Grade 5 provides good weldability and machinability. It can be readily welded using common techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding, enabling the fabrication of complex structures. Its machinability, although lower compared to some other metals, is still considered acceptable with proper tooling and techniques.

Chemical Composition of Titanium Grade 5

| Chemical Composition %, max | ||||||||||

| Specification | Grade | UNS | W.NR. | N | C | H | Fe | O | Al | V |

| ASTM B348 | Gr5 | R56400 | 3.7165 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 |

| AMS 4928 | Gr5 | R56400 | 3.7164 | 0.05 | 0.08 | 0.0125 | 0.3 | 0.2 | 5.5-6.75 | 3.5-4.5 |

| AWS A5.16 | ERTI-5 | R56400 | / | 0.03 | 0.05 | 0.015 | 0.22 | 0.12-0.2 | 5.5-6.75 | 3.5-4.5 |

| ♦ Please contact us for your particular specification or composition requirement | ||||||||||

Mechanical Properties of Titanium Grade 5

| Mechanical properties | ||||||

| Specification | Nominal Diameter | Heat Treatmet | Tensile Strength (MPa,min) | Yield Strength (MPa,min) | Elongation in 4D (%,min) | Reduction of Area (%,min) |

| ASTM B348 | Up to 76.2mm | Annealed | 895 | 828 | 10 | 25 |

| AMS 4928 | Up to 50.8mm | Annealed | 931 | 862 | 10 | 25 |

| AMS 4965 | 38.1~50.8mm | Solution heat treated and aged | 1034 | 965 | 10 | 25 |

| ♦ Please contact us for your particular specification properties requirement | ||||||