General parameters

|

Specification |

Thickness Range |

Width Range |

Length Range |

Tolerance |

Surface Condition |

Delivery State |

|---|---|---|---|---|---|---|

|

Molybdenum Strips |

0.01mm – 3mm |

Customizable |

Customizable |

±5% of thickness |

Smooth, Bright, Matte |

Annealed, Cold-Rolled (upon request) |

|

Molybdenum Foils |

Below 0.1mm |

Customizable |

Customizable |

±0.1mm to ±1mm |

Smooth, Bright, Matte |

Annealed, Cold-Rolled (upon request) |

Please note that the specifications and dimensions may vary based on customer requirements and production capabilities. It is important to consult with your customers and manufacturing team to determine the most suitable specifications for your Molybdenum strips and foils.

Reference standard

- ASTM B386: Standard Specification for Molybdenum and Molybdenum Alloy Plate, Sheet, Strip, and Foil.

- ASTM B387: Standard Specification for Molybdenum and Molybdenum Alloy Bar, Rod, and Wire.

- ISO 4952: Molybdenum and Molybdenum Alloys – Determination of Oxygen Content – Inert Gas Fusion Method.

- ISO 17578: Molybdenum and Molybdenum Alloys – Determination of Sulfur Content – High-Frequency Combustion Method.

- ISO 17579: Molybdenum and Molybdenum Alloys – Determination of Carbon Content – Infrared Absorption Method.

- ISO 17882: Molybdenum and Molybdenum Alloys – Determination of Copper Content – Flame Atomic Absorption Spectrometric Method.

- DIN 1787: Molybdenum – Wrought Products – Strips and Foils – Dimensions, Tolerances, and Roughness.

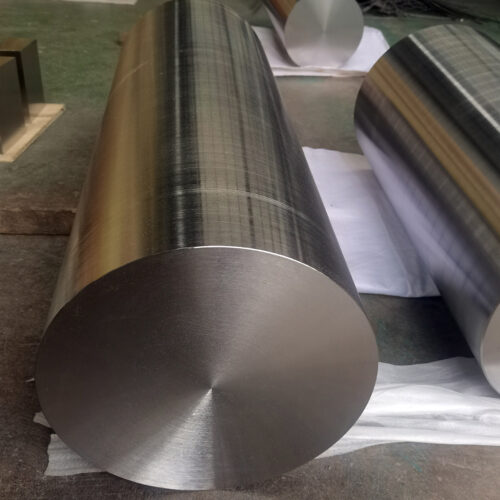

Corresponding grades that can be generated from profiles

|

Grade |

Description |

|---|---|

|

Mo99.95 |

Pure Molybdenum with a minimum purity of 99.95% |

|

Mo99.99 |

Pure Molybdenum with a minimum purity of 99.99% |

|

Mo-La (ML) |

Molybdenum alloyed with Lanthanum for improved ductility and recrystallization temperature |

|

Mo-TZM |

Molybdenum alloyed with Titanium, Zirconium, and Carbon for enhanced strength, creep resistance, and high-temperature performance |

Test items

- Chemical Composition Analysis: Determining the elemental composition of the Molybdenum strips and foils, including the percentage of Molybdenum and any alloying elements present.

- Mechanical Properties: Evaluating the mechanical characteristics of the material, such as tensile strength, yield strength, elongation, and hardness. These tests help assess the material’s strength and its ability to withstand applied forces.

- Surface Quality Examination: Inspecting the surface of the Molybdenum strips and foils for any defects, such as scratches, pits, cracks, or other imperfections that may affect the material’s performance or appearance.

- Dimensional Measurements: Verifying the dimensions of the Molybdenum strips and foils, including thickness, width, and length, to ensure they meet the specified requirements.

- Ultrasonic Testing: Optional testing method used to detect internal defects, such as voids or inclusions, by using ultrasonic waves.

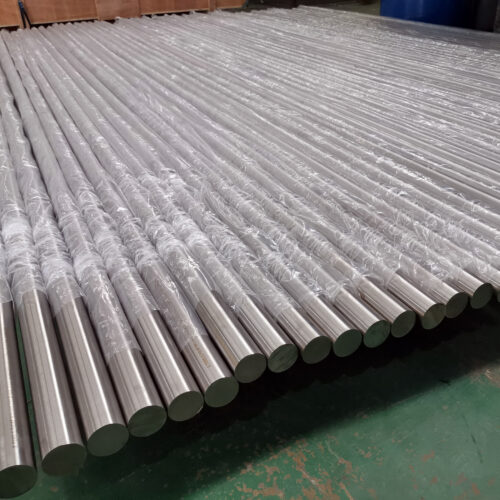

Packing and shipping

- Packaging Materials: Molybdenum strips and foils are often packaged using materials that provide protection against moisture, dust, and mechanical damage. Common packaging materials include plastic films, polyethylene bags, or vacuum-sealed packaging.

- Coil or Sheet Packaging: Molybdenum strips and foils can be packaged in coils or as individual sheets, depending on the customer’s requirements and the dimensions of the products.

- Protective Measures: To prevent scratches or other surface damage, Molybdenum strips and foils may be interleaved with protective layers, such as tissue paper or plastic separators.

- Secure Packing: The packaged Molybdenum strips and foils are usually placed in sturdy cardboard boxes or wooden crates for added protection during transportation. The packaging should be securely sealed to ensure the integrity of the products.

- Labeling: Each package should be properly labeled with essential information, including product name, dimensions, quantity, batch/lot number, and any handling or storage instructions.

- Transportation: Molybdenum strips and foils are typically transported using reliable shipping methods, such as air freight, sea freight, or land transportation. The mode of transportation will depend on factors like distance, urgency, and customer preferences.