Pure Metal Sputtering Target

Sputtering is a proven technology capable of depositing thin films from a wide variety of materials on to diverse substrate shapes and sizes. The process is repeatable and can be scaled up from small research and development projects to production batches involving medium to large substrate areas.

To achieve the desired characteristics in a sputter deposited thin film, the manufacturing process used to fabricate the sputtering target can be critical. Whether the target material comprises only an element, mixture of elements, alloys, or perhaps a compound; the process to produce that defined material in a form suitable for sputtering thin films of consistent quality is as essential as the deposition run parameters perfected by the thin film process engineers and scientists.

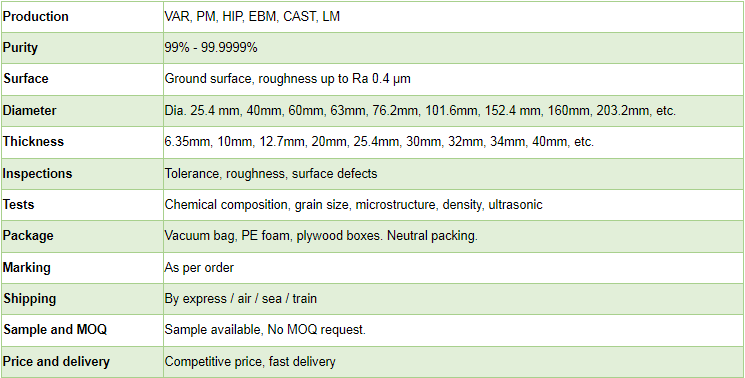

Manufacturing processes we use depend on the properties of the target material and its application. Fabrication methods vary from vacuum melting and rolling, hot-pressed, special press-sintered process, vacuum hot-pressed and forged.

Currently our standard round target sizes range from 1″ to 20″ in diameter, and the rectangular targets are available in lengths up to and over 2000mm in single or multiple piece construction depending on the metal.

Image Box text

Image Box text

Image Box text

Image Box text

ALLOY22 is a Ni-Cr-Mo alloy containing W and extremely low carbon and Si contents.